CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

March 29, 2025

NIOSH research tells us: 10% of subjects failed a fit test after 1 year using the same make, model, and size respirator. Those who have lost more than 20 lbs should prioritize getting fit tested again immediately. Other facial changes requiring fit testing include significant weight gain, extensive dental work, scarring, or cosmetic surgery. Source: https://www.cdc.gov/niosh/npptl/pdfs/Fit-test-10...

Read More

March 29, 2025

Imagine the purchasing manager announcing at a staff meeting that the business is changing the supplier for one of your PSM/RMP-covered chemicals. There is nothing special about this chemical; it is a 100% pure solution/gas, so you think nothing is changing. But this chemical has come under a lot of questions by yours truly, and in fact, a simple change in vendor will impact the Process Safety Information...

Read More

March 29, 2025

It is great when I can convince an organization to pressure test and leak test its process piping. However, if this task is not done according to the book, we may have created a serious hazard. Two (2) safety-critical devices are often overlooked during pressure and leak testing, and missing either one or both can lead to disastrous consequences. Pressure Relief Device Calibrated Pressure Gage Let’s...

Read More

March 28, 2025

Initial findings in an employee’s death show breathing air was compromised while working in a paint booth after the breathing air system unintentionally allowed nitrogen to get into the system. The worker, 61, was found not breathing just after noon on Feb. 24 in a paint booth. This incident occurred in the same area where a December 2019 nitrogen gas-line explosion sent more than a dozen workers to...

Read More

March 27, 2025

This is why we MUST have a Quality Assurance process in our piping installations when welding joins the pipe. The same applies to the construction process vessels; however, most of those are “shop-built,” and we are outside the scope of those vessels. But a “field-erected” vessel would fall into our sphere of control.

Read More

March 26, 2025

PRAYERS and RIP 🙏 This is why we NEVER step in puddles… MINE FATALITY – On August 4, 2024, a contractor suffered severe chemical and thermal burns after he stepped into a deep opening in the floor obscured by puddled liquid. The contractor fell into a mixture of hot water and caustic liquid. On September 2, 2024, he died from his injuries. Best Practices: ➡️ Install adequate warning signals and...

Read More

March 26, 2025

One of the top questions I get in my process safety circles is… Do we have to pressure test/leak test piping that has been opened/modified before we re-introduce the HHC/EHS to the piping? I turn to one of my favorite sources for RAGAGEPs, NFPA, and one of the best NFPA codes is NFPA 58, which I use as my baseline RAGEGAP for all my flammable liquified pressurized gases. Now, I do take issue...

Read More

March 25, 2025

The U.S. Chemical Safety and Hazard Investigation Board (CSB) marked the 20th anniversary of the fatal explosions and fires at BP America Texas City Refinery in Texas City, TX, that occurred on March 23, 2005. The tragic incident resulted in the deaths of 15 people and injuries to 180 others. To remember this deadly event, the CSB released a new report titled “The 20th Anniversary of the 2005...

Read More

March 24, 2025

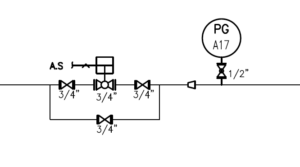

Processes that handle Liquified Pressurized Gases are required to have Hydrostatic Relief Valves on liquid piping where the liquid can be trapped. Much like vapor/gas phase Pressure Safety Valves, it is frowned upon when we have an intervening valve under the PSV. However, many codes today ALLOW us to install a 3-way valve below the Hydrostatic/Vapor/Gas PSV. Interestingly enough, NFPA 58 allows this,...

Read More

March 23, 2025

The arrangement below is very common in processes/systems. This simple yet common arrangement causes havoc in hazard analyses. As the title states, is this arrangement managed with a Temporary SOP, a Car-Seal, or Both? The issue is that the motorized valve is tied to a Hi-Hi level alarm and interlock. When the vessel archives its Hi-Hi level, the interlock CLOSES the motorized valve to STOP flow to...

Read More

March 23, 2025

Several clients design Double Block and Bleed (DB&B) isolation into their process, especially when they know they will regularly enter certain Permit-Required Confined Spaces (PRCS). When these DB&B arrangements are part of the design, the isolation valves and the bleed valve are near one another. This allows us to use a single lock with some cable/chain and lockout devices. … HomeRead...

Read More

March 23, 2025

We often encounter an organization that conducts LOTO training annually. They do this because they believe OSHA requires annual LOTO training. However, the standard, 1910.147, does NOT require annual training! The standard requires each authorized employee to be “inspected” annually. If they fail that inspection, the standard requires the authorized employee to be re-trained. OSHA does...

Read More