One of the scariest things I have learned in my career, going all the way back to my days as a FF, was the when I learned about the “correction factor” that atmospheric monitors come with. I had used these devices for years, even entering some PRCS for “recovery” (sorry not many actual rescues as a FF – we usually show up too late!). But I have to give credit to Jeff Steen, my boss at Murray State University’s Physical Plant EHS Department and one hell of a HAZMAT instructor. It had to be 1990-91 and MSU received a NIOSH grant to establish a regional OSH training center. I was in the maiden PRCS Rescue Course (being a student and FF in a small town has its perks) for the center and Jeff brought in all types of monitors and began training us on their uses and LIMITATIONS and I about fell out of my chair that day. But now, it seems as technology has advanced, the span of the “correction calculation” (a dated term to use in 2018/19) seems to be growing by leaps and bounds! What does this mean, well Xylene is no longer the champion for the greatest correction factor at 2.7. This month I was doing my final 40-hr HAZMAT course for a client and they broke out their new toys and among them was a brand new atm meter (I will not call out the manufacturer here). This brand new model 4-gas meter had all the bells and whistles you could put on a meter, but that meant absolutely nothing. And yes, this meter had been lying to them in a BIG WAY.

This new meter, as all its friends do, has a LEL sensor and this sensor comes with a HUGE limitation – it is DUMB AS A ROCK as it has no idea what it is actually “sniffing”. This is where we, the human, comes into play when using these devices! We, the user, MUST know a couple of key factors BEFORE we can safely rely on our LEL meter. These are:

- The flammable gas/vapor

- The flammable gas used in our calibration gas

- The “correction factor” for our meter based on #1 and #2

You see, even with the newer catalytic bead LEL sensors, they are still DUMB as a rock! When we lower our sample tube into the atmosphere, the meter will have NO WAY of knowing which flammable gas/vapor is present. It will recognize the presence of the flammable gas/vapor, but it will not be able to distinguish toluene from ethanol. This means the LEL% reading on the face of the meter will in most cases NOT be accurate. The only way the LEL% reading will be close to being accurate is when the gas/vapor we are measuring is the same gas that was present in the calibration/bump test gas.

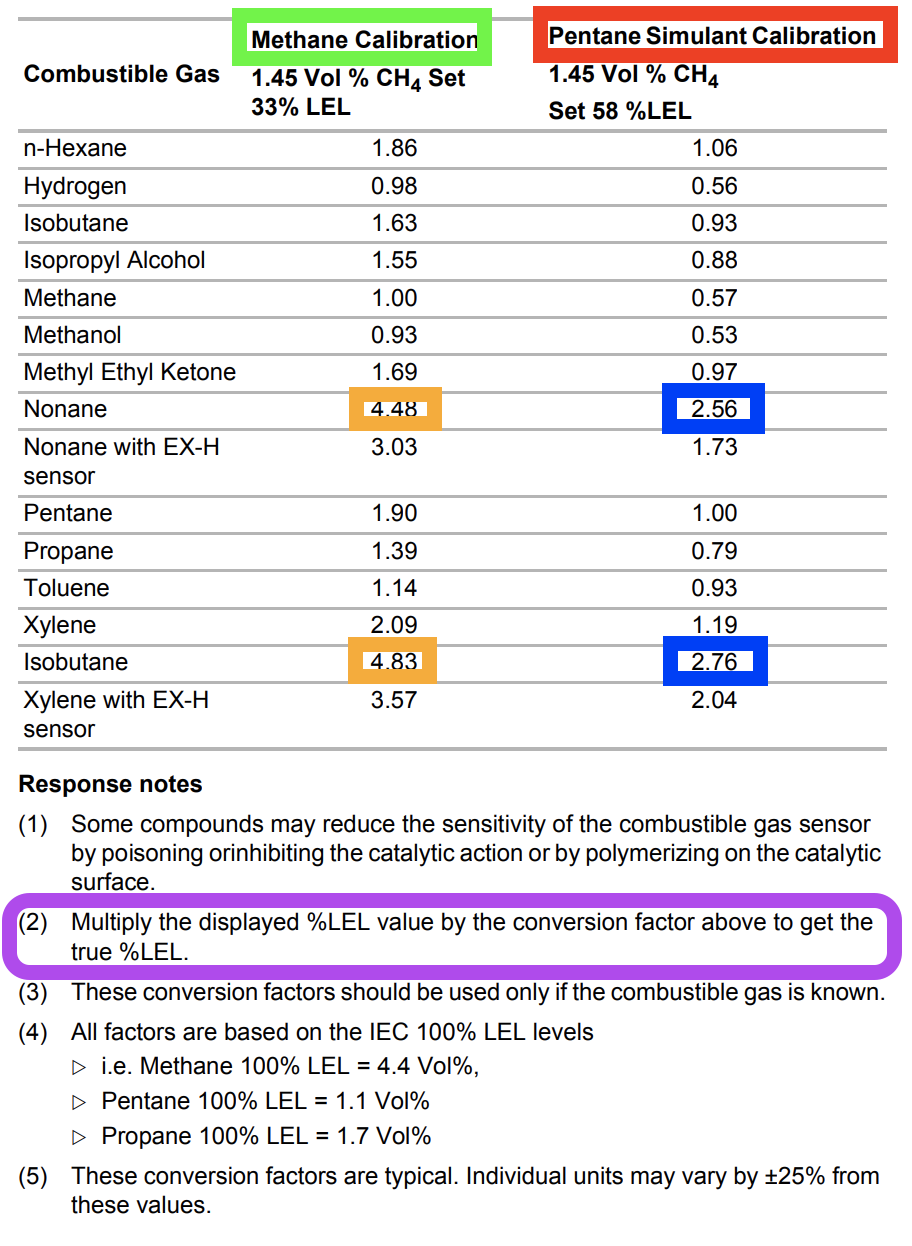

With that said, the two (2) most common flammable gases used in Calibration/Bump gases are Methane and Pentane. Depending on which one of these flammables is in our calibration/bump gas, the reading(s) on our LEL meter can vary greatly. Using the actual data (see table below) from one of the top sellers of 4-gas meters, we can see first hand the wide variation we can have when reading a flammable atmosphere. Keeping in mind that OSHA has established a 10% LEL for the flammable gas/vapor within a CS/PRCS. Once the atmosphere reaches (or has the potential to reach) 10% of the LEL for the flammable gas/vapor, the atm inside the space is deemed Hazardous.