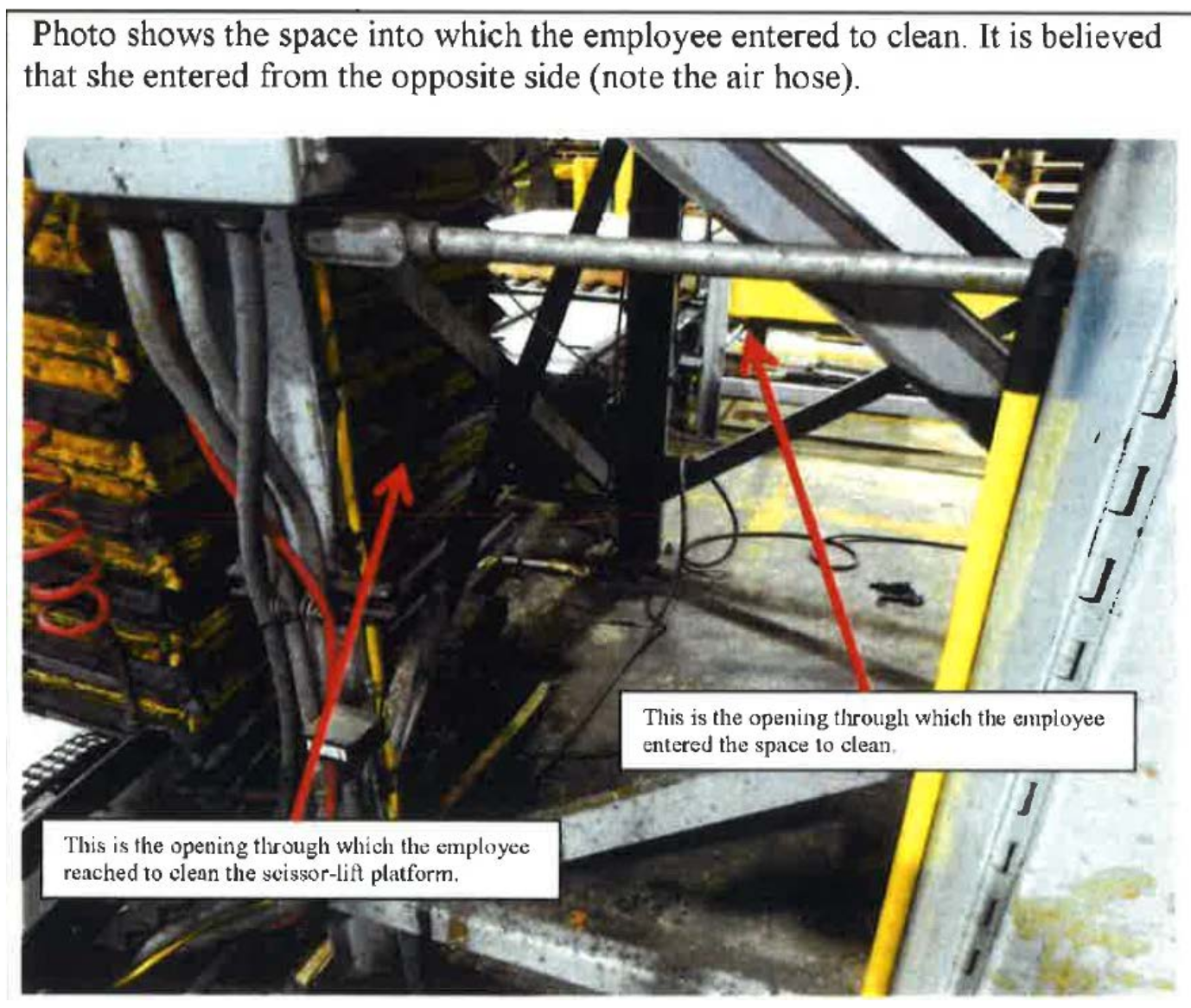

A 41year old female was fatally injured when she was crushed between a pallet lift and the frame of the machine. The victim was a temporary employee assigned to operate a machine called a pallet de-stacker. The overall process utilizes three stationary conveyor platforms and one conveyor platform fitted with a scissor-style lift (scissor-lift platform). The stationary platforms utilize an electronic “eye” recessed in the floor of the platform that senses the presence of a pallet, causing the chain conveyors to automatically start and stop. The scissor platform is similar; however, when the presence of a pallet is detected, the scissor lift operates, raising the platform at a speed of two feet per second. In addition to the platforms, a square magnetized “head” extends outward to pick a layer of cans to place them on a conveyor. The entire process is automatic as long as the operator sets the controls as such: there is also a manual function. Assuming the controls are in automatic, the process begins when a forklift operator places a pallet of product (cans of beans) on the stationary platform furthest to the right of the scissor-lift platform (assuming the operator is facing the scissor-lift platform from the operator platform). The electronic eye triggers the conveyor to move the pallet to the left and assuming the scissor-lift platform is in the down position and empty, that platform will move the pallet to the left and onto the scissor-lift platform. Once the electronic eye on the scissor-lift platform detects the pallet, the platform will raise at a speed of two feet per second. The magnetized head and scissor-lift platform work in tandem (with the use of sensor equipment) to systematically and automatically unload the entire pallet. Once the pallet is empty, the scissor-lift platform will lower to the down position and the conveyor will move the empty pallet to the left and onto the last stationary platform, where it will be removed from the machine. Interviews indicated that the victim was observed cleaning around the machine with a broom and an air hose, first sweeping the platforms and then utilizing the air hose to blow out the recessed openings containing the electronic eyes. Apparently, the operator controls for the de-stacker were in the “automatic” position so when she unintentionally activated the electronic eye, causing the platform to lift, catching her and pulling her into a pinch-point between the platform and machinery frame.