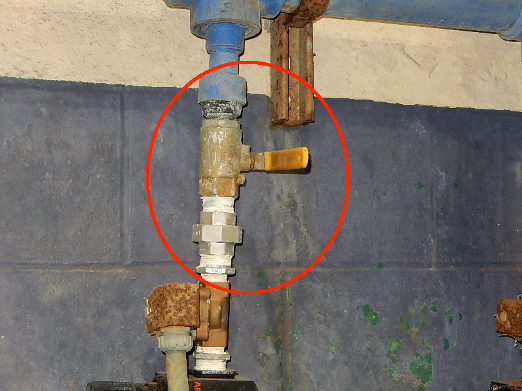

Earlier today I posted a recent OSHA citation where a facility was cited for not having procedures regarding the means to isolate and verify ZES for pneumatic energy sources (i.e. plant air). For some reason, on nearly all of my LOTO projects I find that air sources are a bastardized source of energy when it comes to a means to isolate it and verify it is at a Zero Energy State (ZES). A typical air set up is a drop line off a header, which may or may not have a 1/4 turn ball valve at the end of the drop. At the end of the drop, there is usually a hose connected which conveys the air source to the machine/equipment. Hose or hard pipe, it really does not matter for the purposes of this article. Here is an example from one of my procedures over the years:

9 times out of ten, facilities will say something like “CLOSE and Lockout valve #XXX”. And this is NOWHERE near a Safe State! As we can see in the picture, the valve is CLOSED and I can apply my LO Lock to the valve, but the equipment below the valve is still ENERGIZED at its FULL pressure. The procedure MUST include a means to “release the stored energy” AND a means by which we can verify the air pressure is at its ZES. This is where a bleed/vent and gauge come in handy!

But we can make this really easy for just a few dollars more; behold a DUMP VALVE with a built-in gauge: