INCIDENT OVERVIEW

An ammonia release resulted in the temporary shutdown of an ammonia plant in an industrial food processing facility.

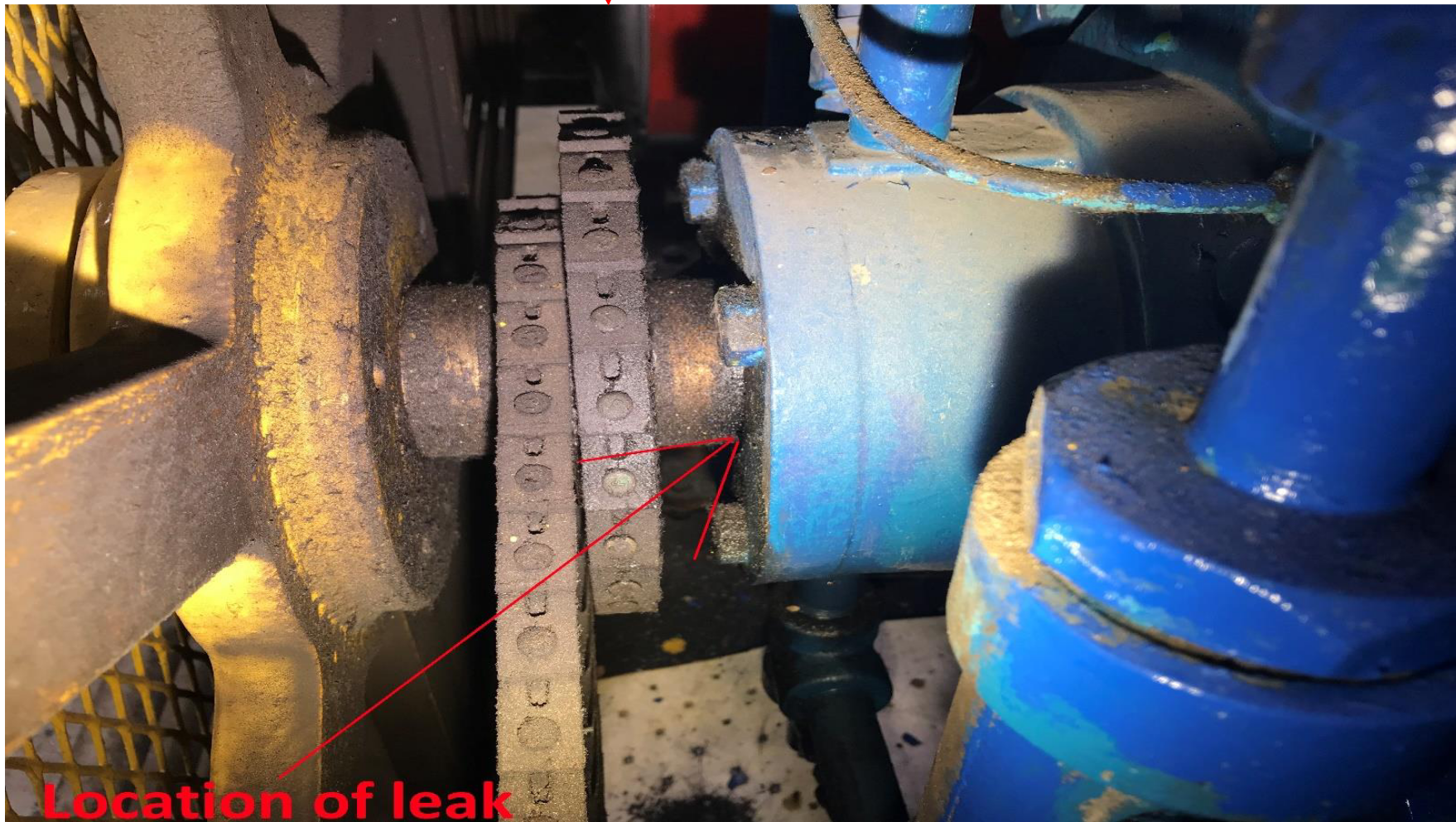

Ammonia refrigeration systems are designed to operate at 250 pounds per square inch gauge (Psig). The major components of the system like compressors, evaporators, liquid receivers, piping, and fittings, etc. are installed in a machinery room. The compressor sucks refrigerant gas into a cavity, gradually reduces the volume of the cavity, and discharges the refrigerant as a high-pressure gas. Lubricating oil is very significant to keep the compressor in good operating condition. To prevent refrigerant gas and oil leakage from the compressor, a reliable mechanical seal assembly is used for the shaft seal of the rotor. A mechanical seal assembly is mainly composed of a “rotating ring” installed on the rotor shaft and a “stationary ring” installed in the seal cover. The rotating ring rotates with the shaft and slides against the stationary ring while maintaining a micron class gap. The lubricating oil provides a seal for this micron class gap. A machinery room is an airtight room that is equipped with ammonia detectors. The ammonia detector automatically starts the ventilation system and also actuates an alarm upon ammonia detection.