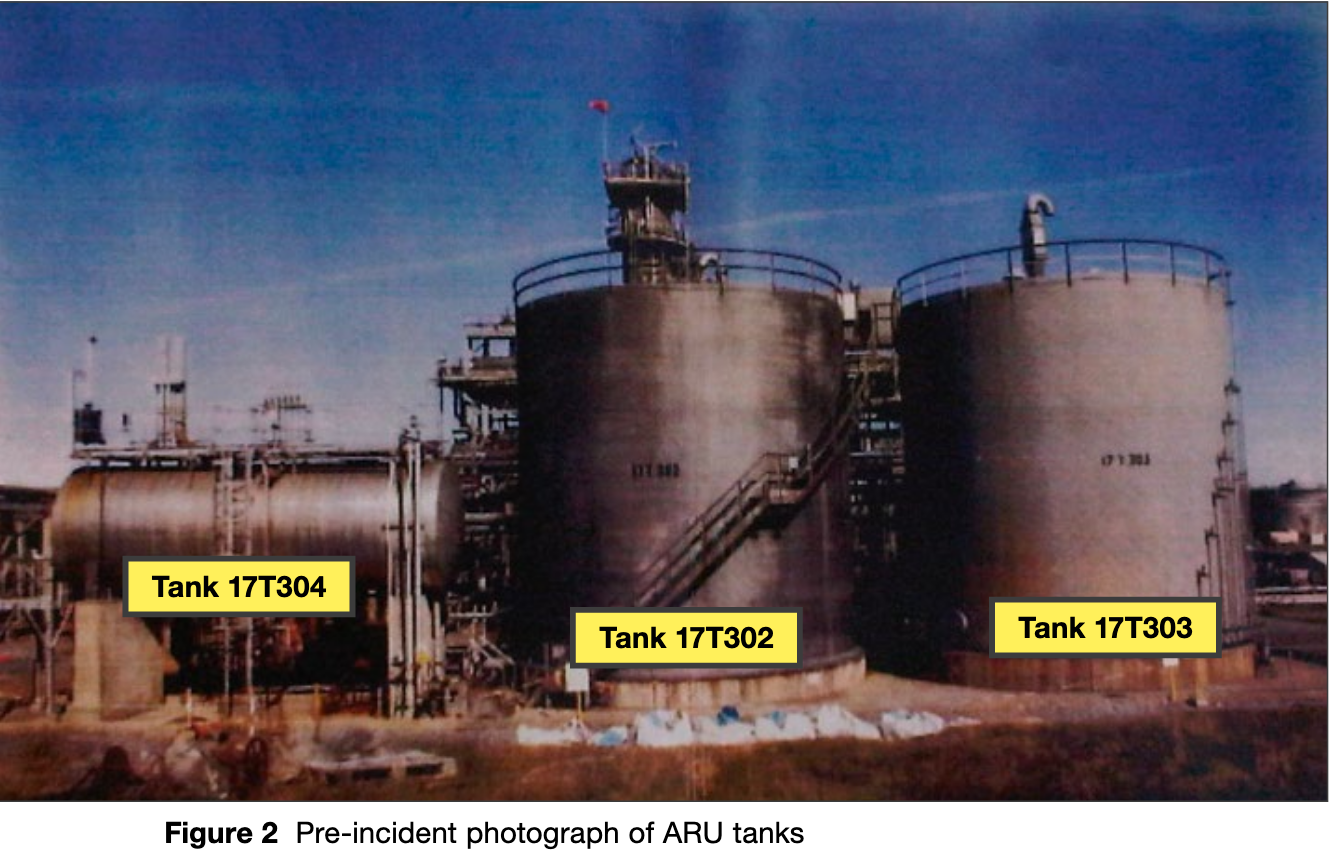

Shortly after 6 pm, on June 2, 2011, an atmospheric storage tank within the amine regeneration unit exploded. A fireball split the tank open and killed four (4) workers. The sole survivor sustained severe burns and suffered life-changing injuries. The force of the explosion ejected the five-ton steel tank roof over 180 feet through the air. After narrowly missing a multi-fuel pipe track, the roof crashed onto a pressurized storage sphere containing extremely flammable butane. Good fortune prevented the airborne roof from puncturing the butane storage vessel, which would have led to an uncontrolled release of liquified petroleum gas (LPG). The explosion was caused by the unintended ignition of a flammable atmosphere within the tank (17T302), during what should have been a routine cleaning operation conducted in preparation for maintenance. The investigation revealed a longstanding and widespread failure to understand and control risks posed by the flammable atmosphere inside the tank. The explosion and the resulting fatalities were therefore avoidable. The incident was not merely the consequence of errors by individual employees, but because of the failure of safety management systems to ensure a safe place and safe systems of work.

This is a MUST READ for safety professionals who deals with flammable atmospheres inside and outside of process vessels. A 30′ tall tank was only sampled 5′ into it and was found to have 67% LEL readings on the portable gas meter. The SWP was approved and the explosion occurred.

Safety management system failings: