This accident happened at a site of a distributor of bulk chemicals such as acids, bases, aqueous solutions of detergents, etc. The chemicals are delivered by tanker truck or railcars and put into tanks. The chemicals are then filled in drums or cans which have a volume ranging from 5-gallon cans to 55-gallon drums. At the site, there is also a company administration building, a laboratory, small-scale production rooms, and a warehouse. Just over 100 yards away there is a public street. The involved unit consists of a storage unit with 13 tanks of 8,000-gallon volume, a delivery station for tank trucks at a distance of about 160′ to the tanks and a filling station for drums and containers from 5-gallon cans to 55-gallon drums. The chemicals stored in the unit are acids such as nitric acid, sulphuric acid, and hydrochloric acid. Furthermore, caustic soda, FeCl(III)-solution and sodium hypochlorite solution are stored there.

This accident happened at a site of a distributor of bulk chemicals such as acids, bases, aqueous solutions of detergents, etc. The chemicals are delivered by tanker truck or railcars and put into tanks. The chemicals are then filled in drums or cans which have a volume ranging from 5-gallon cans to 55-gallon drums. At the site, there is also a company administration building, a laboratory, small-scale production rooms, and a warehouse. Just over 100 yards away there is a public street. The involved unit consists of a storage unit with 13 tanks of 8,000-gallon volume, a delivery station for tank trucks at a distance of about 160′ to the tanks and a filling station for drums and containers from 5-gallon cans to 55-gallon drums. The chemicals stored in the unit are acids such as nitric acid, sulphuric acid, and hydrochloric acid. Furthermore, caustic soda, FeCl(III)-solution and sodium hypochlorite solution are stored there.

The accident happened during a period of rebuilding of the unit; the filling station and the delivery station were in the process of being renewed.

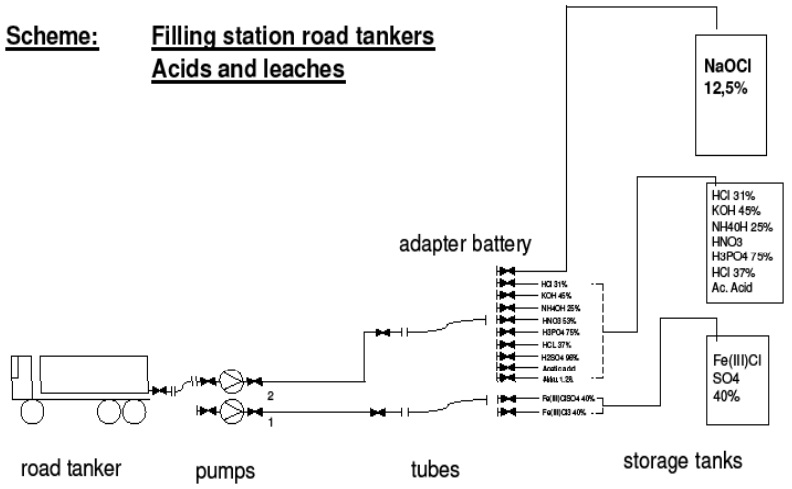

At the delivery station for tankers, there is a connection for FeCl3-Solution and only one connection for all the other chemicals.

A pump transports the fluids via a pipe to a connection battery/filling station for drums, which is near the tanks. At the battery, a worker connects the pipe, by using a hose, to the right tank.

Before filling, the road tanker should be weighed, delivery documents checked and a sample of the tanker withdrawn. The sample is analyzed (specific weight) in the laboratory. Then the filling is released.