Without a doubt, the biggest LOTO failure for businesses with a LOTO program is the application of the “minor servicing” exception. (emphasis by me)

|

1910.147(a)(2)(i) This standard applies to the control of energy during servicing and/or maintenance of machines and equipment. 1910.147(a)(2)(ii)(A) An employee is required to remove or bypass a guard or other safety device; or 1910.147(a)(2)(ii)(B) An employee is required to place any part of his or her body into an area on a machine or piece of equipment where work is actually performed upon the material being processed (point of operation) or where an associated danger zone exists during a machine operating cycle. Note: Exception to paragraph (a)(2)(ii): Minor tool changes and adjustments and other minor servicing activities, which take place during NORMAL PRODUCTION OPERATIONS, are not covered by this standard if they are ROUTINE, REPETITIVE, AND INTEGRAL TO THE USE OF THE EQUIPMENT FOR PRODUCTION, provided that the work is performed using ALTERNATIVE MEASURES WHICH PROVIDE EFFECTIVE PROTECTION (See subpart 0 of this part). |

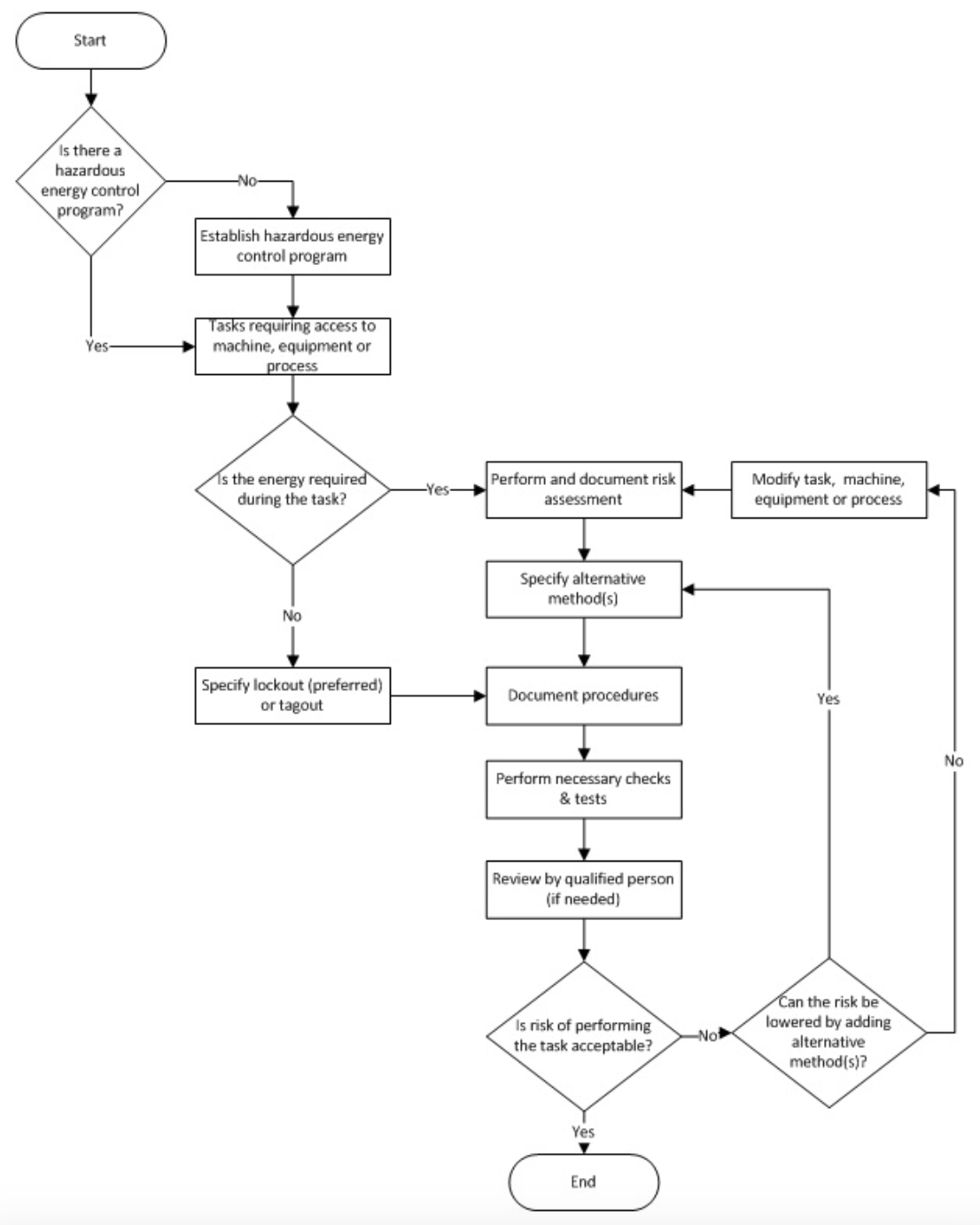

The ANSI standard has simplified the decision-making logic for applying this exception. It is simple, straightforward, and can walk us down a path of safety – if we spend the time and $ to use it! As I said in my earlier post, FIVE (5) hurdles have to be crossed BEFORE we can even begin to consider using this “minor servicing” EXCEPTION:

- The task is part of NORMAL PRODUCTION,

- there is NO EXTENSIVE DISASSEMBLY involved (see CPL 147),

- the task is ROUTINE in production,

- the task is REPETITIVE in production,

- the task is INTREGAL to production.