This is a tale of Valve Handle Positions and the assumption the valve was CLOSED based on the position the handle was found in. No Lockout/Tagout and NO VERIFICATION of a Zero Energy State (ZES) before the NG pipe was disassembled. I am not sure why the NTSB makes no mention of “Energy Control” (e.g. Lockout/Tagout) in this accident report, but it was clear a needed administrative control for the scope of work. OSHA did cite the contractor for lack of LOTO and training issues, but no mention in the NTSB report.

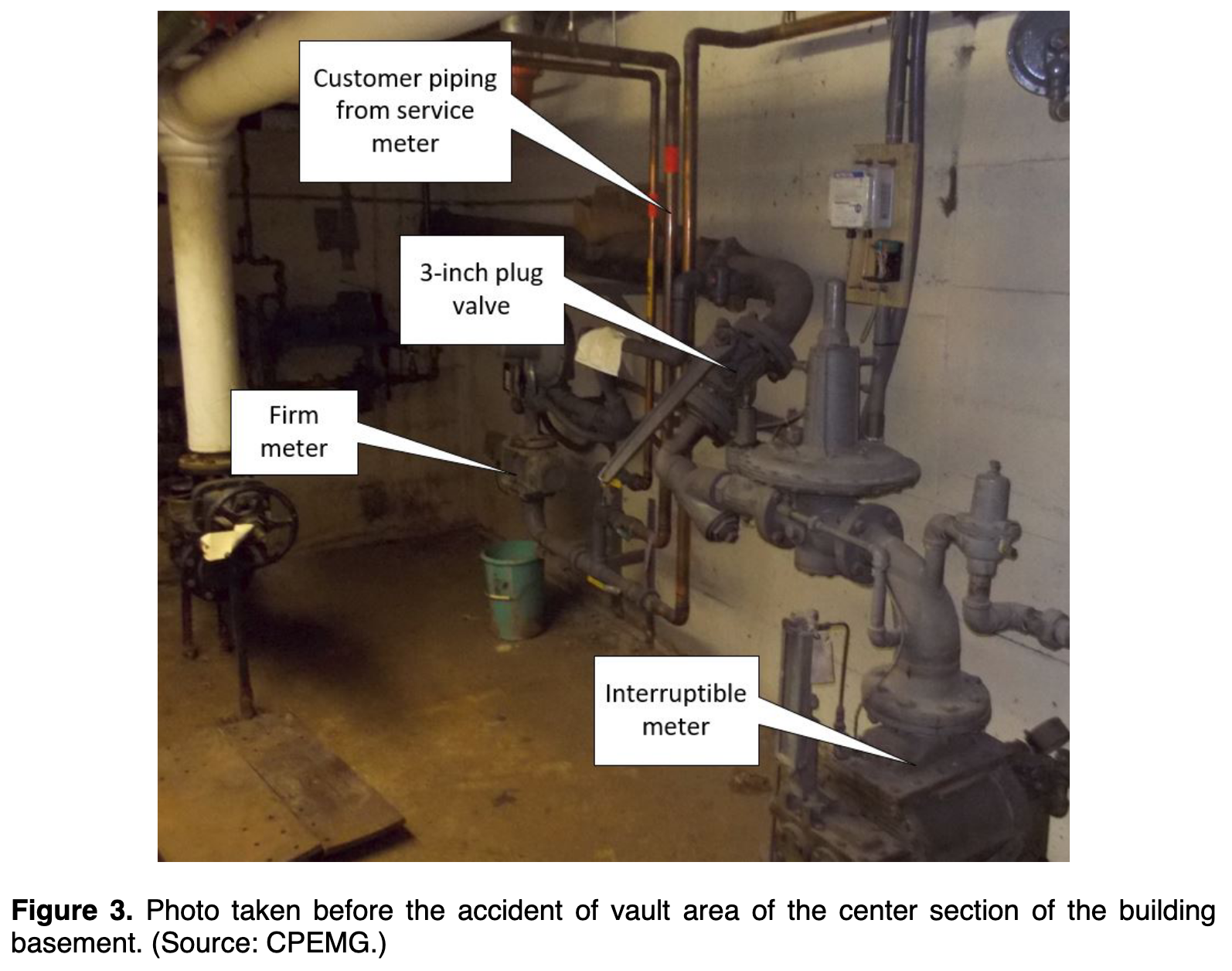

Natural gas service to the school could be shut off using the manually operated customer service valve (also known as a curb valve or fire valve), which was located in an underground valve box (also known as a curb box). Beyond the curb valve, the natural gas supply line penetrated the utility bunker wall and branched to supply gas to the firm and interruptible meters. The branch to the interruptible meter passed through a manually operated plug valve (involved in the accident). The end of the plug is square, for attachment of a handle having a compatibly sized opening to accommodate the square stub on the plug. The handle can be attached in any of four (4) different orientations. The square hole of the handle was also equipped with a setscrew to lock the handle in place. The plug in the valve turns 90 degrees; in one orientation, a passage through the plug aligns with the attached piping and gas can flow; when turned 90 degrees, to achieve the CLOSED position, the passage is perpendicular to the attached piping and gas cannot flow.

On August 2, 2017, at 10:22 a.m., local time, a building on the north campus of a private school in Minneapolis, Minnesota, was destroyed by a natural gas explosion. Figure 1 shows an aerial view of the north campus prior to the accident, with a yellow arrow pointing toward the explosion site. Figure 2 is a photograph of the accident site taken after the building explosion, with emergency responders and gas company personnel on scene. At the time of the explosion, two workers were installing piping to support the relocation of gas meters from the basement of the building to the outside. Two new meters mounted on an exterior wall were ready for the piping to be connected. WHILE WORKERS WERE REMOVING THE EXISTING PIPING, A FULL-FLOW NATURAL GAS LINE AT PRESSURE WAS OPENED. The workers were unable to control the release of the gas; thus, they evacuated the building and warned others to evacuate. The explosion occurred during their evacuation. Two individuals were killed, and nine others were injured.

The National Transportation Safety Board determines that the probable cause of the natural gas explosion was the DISASSEMBLING OF PIPING UPSTREAM OF A GAS SERVICE METER IN THE BUILDING BY A PIPEFITTING CREW, RESULTING IN THE RELEASE OF NATURAL GAS, WHICH SUBSEQUENTLY IGNITED. Contributing to the accident was the lack of detailed documentation that clearly established the scope of work to be performed.