SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

September 12, 2020

At 10:45 a.m. on January 11, 2020, Employee #1, employed by an oil and gas operation company, was overseeing a heater treater welding repair. Employee #2 emptied the remaining fluids in the heater treater. Employee #1 power washed the heater treater to remove any remaining flammable materials and ensure that it was safe for welding. After Employee #1 finished washing the heater treater he notified...

Read More

September 12, 2020

I am not sure what it is about fresh air intake for exhaust ventilation systems, but we should call them “Rodney”, as in Rodney Dangerfield, because they get no respect. As I said in 2016 and 2018 in my articles:

The Ventilation Design Basis begins with our intakes

FRESH AIR intakes for a ventilation system need to be from a source of FRESH AIR!

Here are two (2) photos of a person...

Read More

September 12, 2020

Respondent owns and operates an agricultural storage, feed, and supply business. On or about August 13, 2019, EPA conducted an inspection of Respondent’s Facility to determine compliance with Section 112(r) of the CAA and 40 C.F.R. Part 68. Information gathered during the EPA inspection revealed that Respondent had greater than 10,000 pounds of anhydrous ammonia in a process at the Facility. Respondent...

Read More

September 10, 2020

Many consumers may have never heard of “nitriding”, but just about every metal component in heavy equipment will go through a “nitriding process” to strengthen the metal. And it is this nitriding process that many businesses have a HIGHLY CONFIDENTIAL/PROPRIETARY blend for their process. Seems everyone has a slightly different blend and they hold this recipe near...

Read More

September 10, 2020

It seems that just about every month, even during the COVID Pandemic, we come across a safety professional, 3rd party auditor, and even an OSHA CSHO who will swear on his/her grandmother’s grave that the ONLY acceptable HAZCOM labels in the workplace are those that contain:

Product identifier;

Signal word;

Hazard statement(s);

Pictogram(s);

Precautionary statement(s); and,

Name, address, and...

Read More

September 10, 2020

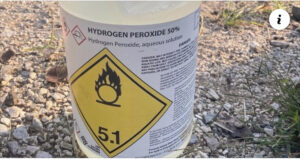

Today a longtime friend and SAFTENG member shared an article in our FaceBook group regarding a food pantry in TN that accidentally gave out fifty-four (54) 1-gallon containers of 50% Hydrogen Peroxide (H2O2) in their food packages. Now I have no idea what a food pantry is doing with 50% Hydrogen Peroxide, much less that quantity. I write a lot about OSHA’s PSM and EPA’s RMP...

Read More

September 9, 2020

NOTE: I have posted this inspection because of the level of detail the inspectors went. There has been a significant shift in the quality of findings from BOTH OSHA and EPA in their process safety inspections. This EPA inspection team was well aware that the IIAR Bulletins are being phased out and replaced with ANSI/IIAR standards. The amount was low, but things could have been much...

Read More

September 9, 2020

NOTE: these are all my Hotwork / Welding related incidents from 1998-2018 Incident Alerts. You can use your browsers “page search” function to search for specific keywords if you are looking for a specific type of accident. MANY of the links no longer work, but I always tried to capture the gist of the incident in my summary.

I have always tried to scrub company names from these reports...

Read More

September 8, 2020

Respondent operates an ammonia refrigeration system which uses 30,345 pounds anhydrous ammonia (ammonia). Respondent has one RMProgram level 3 covered process, which stores or otherwise uses an extremely hazardous substance in an amount exceeding its applicable threshold of 10,000 pounds. On December 21, 2017, the EPA conducted an onsite inspection of the RMProgram related records and equipment for...

Read More

September 8, 2020

CAUTION: This interim order is specific to the facility requesting it. Do NOT use these measures at your facility!!!

If I had a nickel for every time I have heard the excuse… “its more dangerous to do these isolations than it is to do the entry with lesser isolations,” I would not be writing this article instead, I would be on my yacht deep-sea fishing somewhere off the...

Read More

September 8, 2020

At 7:00 p.m. on December 4, 2019, an employee was working at a machine shop. He was operating a CNC (computer numerical control) lathe to machine material. The machine was equipped with an interlock system. The interlock system was supposed to prevent the lathe from functioning if its door was open; however, the interlock system had been bypassed. The narrative did not say who had performed this...

Read More

September 8, 2020

Respondent is the owner and/or operator of a meat processing facility that uses, handles, and/or stores more than a threshold quantity of anhydrous ammonia. Respondent is required to prepare and implement an RMP to detect and prevent or minimize accidental releases of such substances under section 112(r)(7) of the CAA. Respondent meets the Program 3 eligibility requirements under 40 C.F.R. § 68.10. ...

Read More