Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 23, 2024

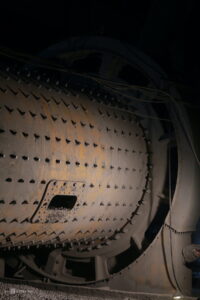

Source: VnExpress/Anh Phu Seven (7) workers were killed, and three (3) others were injured while conducting periodic maintenance on one of the plant’s kilns when the incident occurred. When the workers entered the rotary kiln to start the repair work, the kiln unexpectedly restarted. Replacing the eroded kiln plates is done every 5-7 months and “Things usually...

Read More

April 22, 2024

Since gas use was integral to the UH accident and since compressed gas cylinders present serious safety issues, several specific examples of improper gas and gas cylinder usage are detailed here. 1. Cylinders in the laboratories adjacent to POST 30 as well as in several laboratories located in different buildings, contained Teflon tape on the CGA connection threads to the cylinder valveoutlet (Figures...

Read More

April 22, 2024

He was working for a subcontractor on April 13, 2022, when a GC foreman used a flame torch to dry an area of the floor of an enclosed mechanical room beneath the football stadium as he and another worker were applying a flammable material to the floor. The torch sparked an explosion, and he was burned over 70% of his body when he tried to run from the room but stumbled, spilling primer on himself,...

Read More

April 21, 2024

Both OSHA PRCS standards define and quantify a Hazardous Atmosphere in terms of combustible dust using the distance one can see through the dust cloud… Hazardous atmosphere means an atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue (that is, escape unaided from a permit space), injury, or acute illness from one or more of the following...

Read More

April 21, 2024

VW chose Tennessee for its new assembly plant because it is a “right to work” state. The union campaigns lost in 2014 and 2019, but last week, it won big (2,628 for and 985 opposed), at least based on the NLRB count so far. A few votes are being challenged, but nothing near the number needed to change the overall outcome. Could this be viewed as a cultural indicator? We are...

Read More

April 21, 2024

Some raw materials are sensitive to humidity; this valve sticks and is more demanding than its supposedly similar neighbor; that pump has broken down; this operation sometimes occurs at night and sometimes during the day, sometimes when it’s hot, other times when it’s cold, sometimes our co-worker is tall, sometimes he is short, we may be under pressure time-wise, etc. Thanks to their experience and...

Read More

April 21, 2024

The story behind this picture is said to be a 19-year-old granddaughter’s attempt at designing for her grandfather’s dementia.

Human Factors Engineering (HFE)!!!

Making human factors matter by REDUCING the opportunity for error.

It really can be this simple!

Pic Credit: Amy Dalton

Read More

April 20, 2024

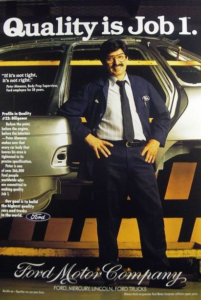

If you have ever attended one of my SMS presentations or training courses, you know I am a huge Edward Demming fan. I started my career during the ISO 9001 era, which many call the “Quality Era.” Do you remember Ford’s slogan in the 1990s? “Quality is #1,” and the ISO quality movement was considerably driven by automobile manufacturers such as Ford, GM, etc. ...

Read More

April 20, 2024

The following incident is a precautionary example of the potential hazards of improperly depressurizing piping to remove a hydrate. During production operations, a control room operator observed a decrease in gas lift pressure supplied through a pipeline to a remote well location. The control room operator notified the onboard platform operators of the pressure drop and the possibility of a hydrate...

Read More

April 19, 2024

One of the finest men I ever worked for, Jim Krumholz, taught me this trick in 1999! Manager MUST attend the “safety training” their employees attend! Even if this manager would never participate in an entry into PRCS, perform HW, or even participate in a lockout, they need to understand the expectations of their team members and how safety integrates with their team’s daily activities....

Read More

April 19, 2024

On January 13, 2022, workers inside the company’s fabrication shop performed a “wet test” on a newly built tank truck to check for leakage. This entailed running diesel test fuel through different tank compartments and other truck components. This was a routine operation at the workplace. Workers knew never to use gasoline, and the company had a standard operating procedure that prohibited...

Read More