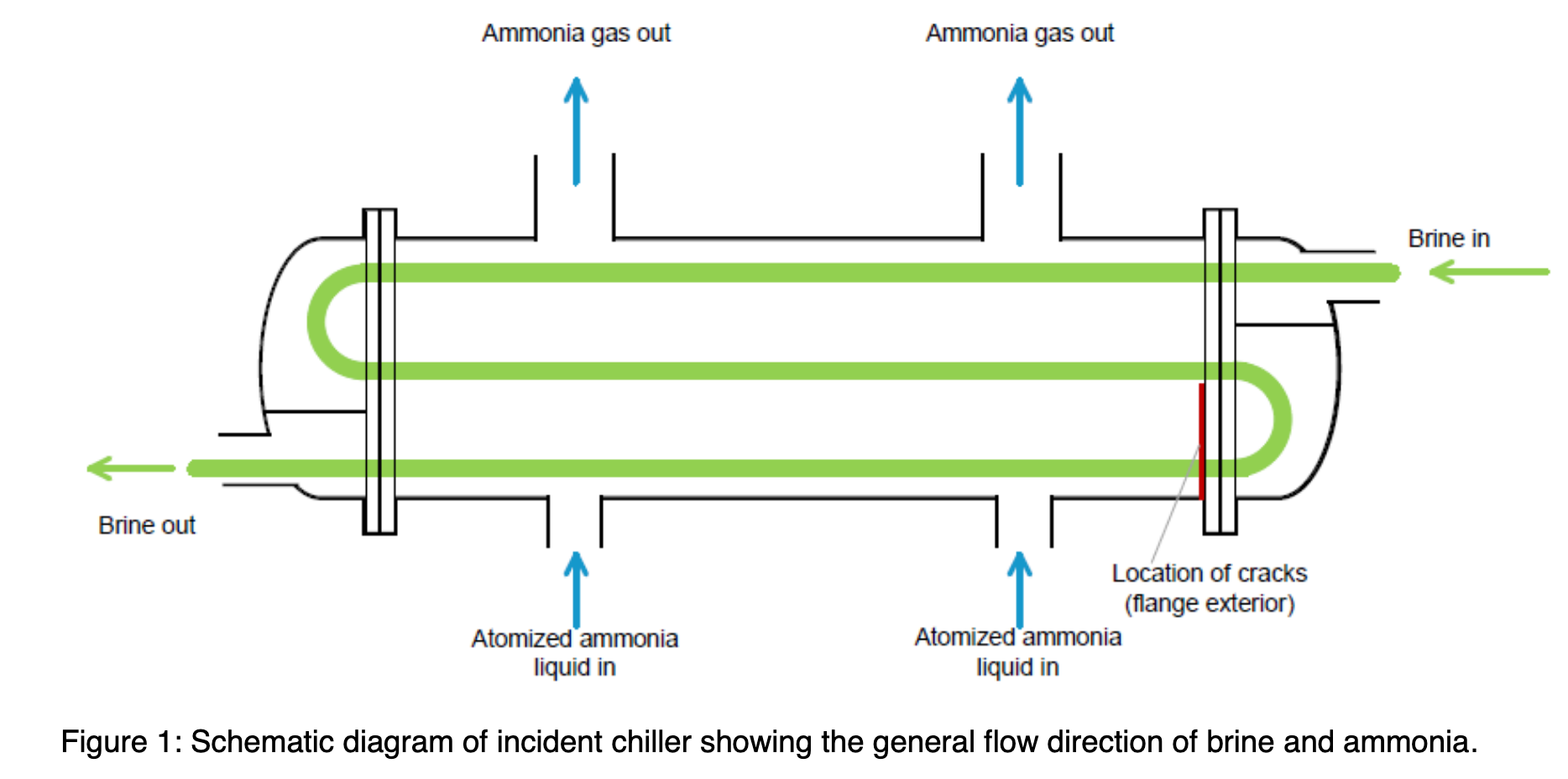

A new direct expansion chiller was installed at an ice arena to replace an existing chiller. After almost 20 weeks of service, an ammonia leak was detected, which released ammonia into the machinery room. The low level (25 ppm) ammonia alarm sounded and the ventilation system was activated to continuously evacuate vapors to the outdoors while the location and nature of the leak were investigated. The plant remained operating for approximately two days in this leaking condition before the source of the leak was found. The source was found to be a crack in the chiller shell. The plant was shut down by the City on order from Technical Safety BC due to the uncontrolled nature of the leak and due to uncertainty around the condition of the chiller vessel.

Small cracks grow up to become big cracks and big problems (NH3 direct expansion chiller)