One of the most common valves used in industrial settings is the 1/4-turn ball valve. From 1/4″ up to 6″, these valves are everywhere, regardless of the risks they may pose. Recently a client and I discussed these valves and their risk in highly hazardous chemical processing. I have had several incidents over my career where this type of valve led to LOPC events, some of which were severe. The discussion centered around process safety, but what got our attention was their use in energy control/LOTO and Car-Seal.

One of the most common valves used in industrial settings is the 1/4-turn ball valve. From 1/4″ up to 6″, these valves are everywhere, regardless of the risks they may pose. Recently a client and I discussed these valves and their risk in highly hazardous chemical processing. I have had several incidents over my career where this type of valve led to LOPC events, some of which were severe. The discussion centered around process safety, but what got our attention was their use in energy control/LOTO and Car-Seal.

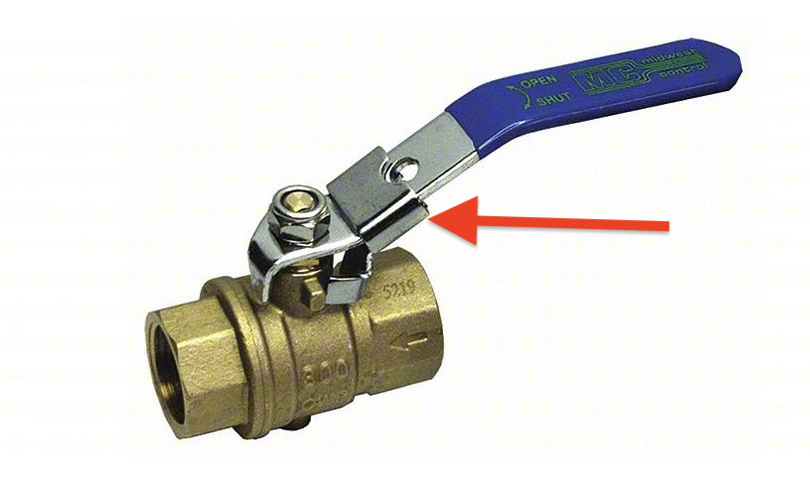

These valves, by design, require the operator to move the valve handle 1/4 of a turn to OPEN/CLOSE the ball valve FULLY. This means that once the handle is moved, even the slightest, we have flow through the valve. This small movement can be disastrous in many situations. So the question was asked, if we allow these 1/4 turn valves in the process, should we require they be equipped with the sliding/lockable tab (see red arrow in image)? This sliding tab physically prevents the handle from moving the slightest; however, the $60,000 question was: Can we lock out one of these valves WITHOUT the sliding tab so the valve will securely stay closed? The results are in, and it was a unanimous decision…