A 60-year-old welder fell 32 feet while constructing the leading edge of a storage tank roof. His employer was an aboveground storage tank manufacturer. He had over 40 years of job experience. He was with three other workers constructing the leading edge with sheets of metal sheathing. The roof was 76-feet wide by 34.5-feet high, with a 1 in 12 pitch. He was acting as a “spotter” for a crane operator who was hoisting the sheets to cover a 16-foot hole remaining on the roof.

A 60-year-old welder fell 32 feet while constructing the leading edge of a storage tank roof. His employer was an aboveground storage tank manufacturer. He had over 40 years of job experience. He was with three other workers constructing the leading edge with sheets of metal sheathing. The roof was 76-feet wide by 34.5-feet high, with a 1 in 12 pitch. He was acting as a “spotter” for a crane operator who was hoisting the sheets to cover a 16-foot hole remaining on the roof.

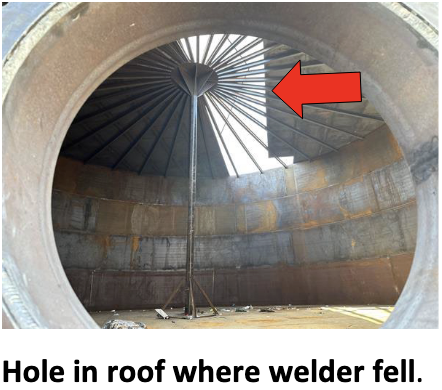

After unloading the sheets, he needed to tack weld one near the center peak of the roof. He stepped from the leading edge to a rafter over part of the hole. He then sat down on the rafter and extended his legs two and a half feet across the hole to another rafter. While sitting on the rafter, he used a pry bar to bend and move the sheet into place for welding. As he pried, he fell backward through the hole between the rafter and leading edge. After landing on the ground, he was badly hurt but still conscious and breathing. Emergency responders arrived and had a critical care helicopter airlift him to the hospital. He died the next day.

Following the incident, investigators found:

- The welder and his co-workers had tied off while riding a boom lift to the roof, but their supervisor allowed them to remove their personal fall arrest system (PFAS) harnesses on the roof.

- The workers and their supervisor discussed the fall hazards and the general contractor’s fall protection expectations on the roof, but they chose not to use PFAS believing that lifelines would create a tripping hazard.

- The employer lacked a fall protection work plan (FPWP) and did not know about state requirements to have one. The supervisor only told the workers not to walk out on the rafters. The project manager also never conducted any safety inspections at the job site.

CLICK HERE for the report