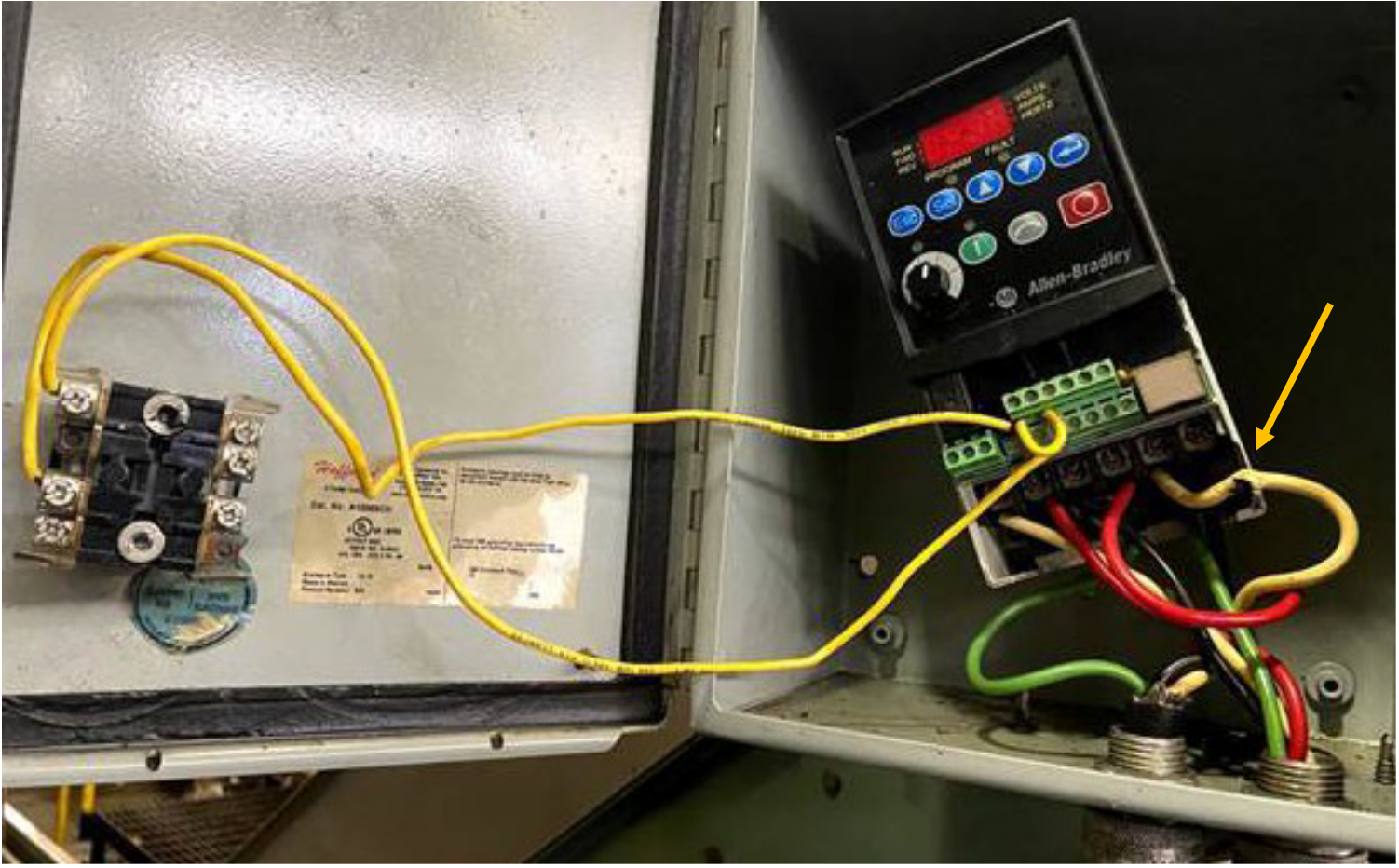

We should NEVER accept damaged electrical wires – EVEN when they are inside an electrical cabinet! Case in point…

We should NEVER accept damaged electrical wires – EVEN when they are inside an electrical cabinet! Case in point…

A 30-year-old male employee was troubleshooting an issue with an injection molding machine and apparently was electrocuted when he contacted the frame of the loading conveyor. The company is a manufacturer of injection-molded, polyvinyl chloride (PVC) schedule 40 and schedule 80 pipe fittings (e.g., couplings, elbows, reducers) and other fittings of varying sizes.

It was learned that there was an issue with the parts being manufactured by injection molding machine #B-19. The victim was troubleshooting the injection molding machine to determine why water was getting in the parts during the injection molding process. The injection molding machine was manufacturing PVC threaded male adapters from PVC pellets that the company received in bulk. The finished threaded male adapters fell from the opened mold sections of the injection molding machine onto the loading end of a parts conveyor. The adapters rode the parts conveyor up an incline and were dropped into a large storage or shipping container at the unloading end of the parts conveyor. The 480v parts conveyor was a portable unit equipped with an appropriate cord and plug so it can be relocated or repositioned per the needs of the facility and/or the production schedule.