Leave it up to FM Global to lead the way in Hot Work Safety. I know in my career there has been no other force in hot work safety like FM Global (Formerly Factory Mutual). And I am guessing that all of these large loss fires in the construction industry these past couple of years has gotten a lot of insurance companies attention. So last month, FM Global issued a revised Property Loss Prevention Data Sheet on Hot Work (DS 10-3 HOT WORK MANAGEMENT) and in this revision FM Global has:

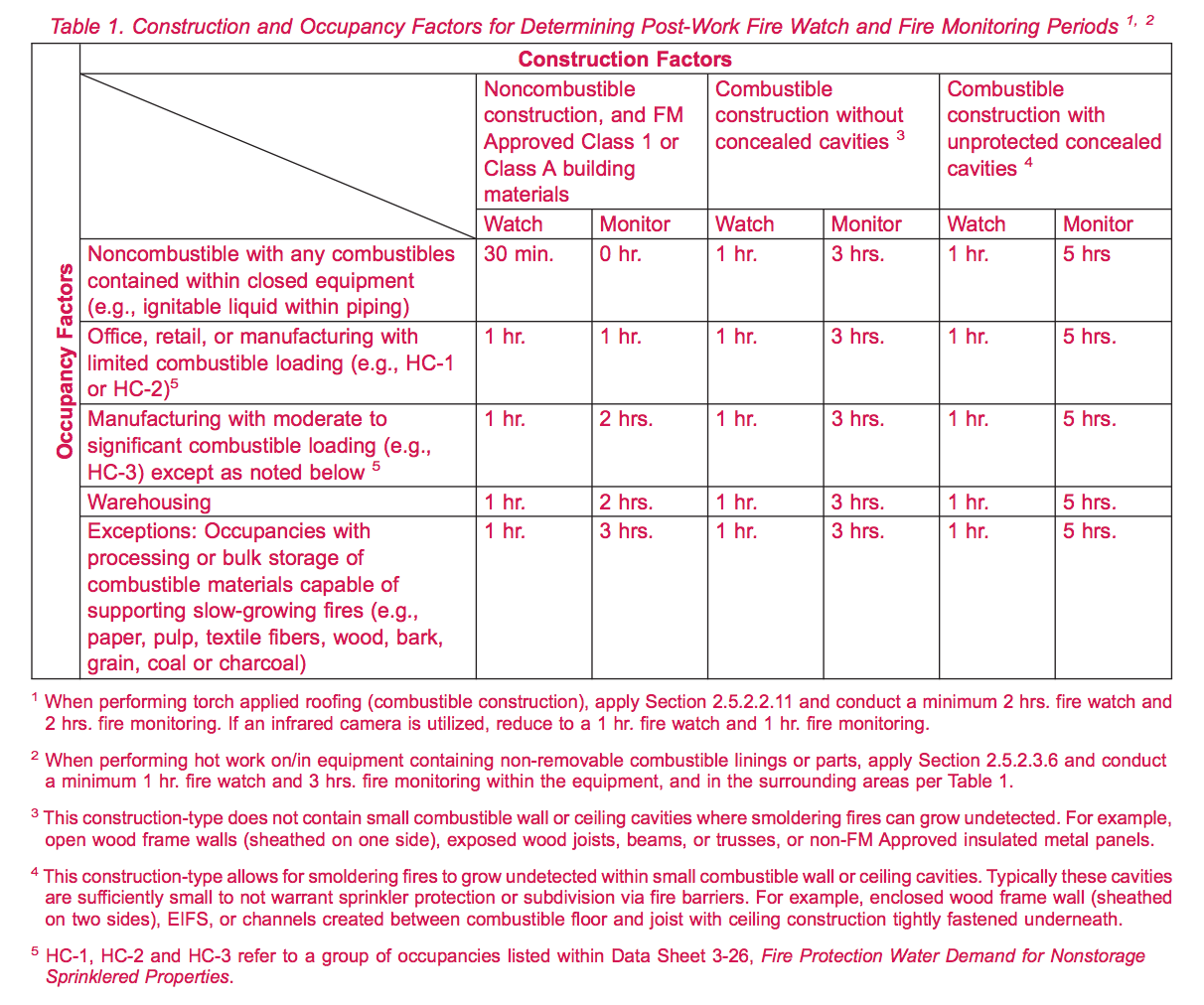

- simplified and combined tables related to post-work fire watch and monitoring periods,

- added further torch applied roofing guidance,

- added Appendix D – Sample Hot Work Permit (highly recommended if you’re looking to improve your HW permitting process) which now reflects the newer Fire Watch requirements, and

- other minor editorial changes were made.

Improperly managed hot work remains a leading cause of large fires and explosions. Based on a review of FM Global loss history, the following conclusions were drawn regarding key factors in hot work losses:

- Failing to identify and isolate combustible construction in the hot work area increases the likelihood and severity of a hot work fire.

- Failing to identify and isolate combustibles in a hot work high-risk area increases the likelihood and severity of a hot work fire.

- In-service fire protection systems significantly reduce the severity of a hot work fire.

- The overwhelming majority of hot work fires occur while the work is being done or within 60 minutes of completion, highlighting the importance of a fire watch both during and following hot work.

Here are the significant improvements and their new Fire Watch Table, but I strongly encourage you to visit FM Global Data Sheets and register (FREE) and download DS 10-3 HOT WORK MANAGEMENT. I highly recommend these Data Sheets as both educational readings for people in risk management roles and as a means to greatly improve safe work practices at industrial facilities. As I have said in the past, if your management won’t splurge and buy full RAGAGEPs, these are your next best bet to get the facility heading in the right direction.

Disclaimer: FM Global is a “Partner in Safety” but they are no longer required to pay membership fees. This is an unpaid and unsolicited posting and I fully endorse FM Global Data Sheets.