Based on the feedback from other SAFTENG members, I have made this article public for the next 30 days.

Much like the process safety debates around valve/equipment labeling, no RAGAGEP specifically requires a unique identifier on every valve or piece of equipment. Yet, labeling valves/equipment within the covered process is necessary to manage the process’s safety. Another debate we have on a FAR TOO OFTEN frequency: labeling/demarcating Hazardous Locations (HAZLOCs). Having a HAZLOC drawing where the distances and heights are specified is one thing; having these areas labeled/demarcated in the plant is very different and much needed.

Growing up in the petrochemical and semiconductor industries, my facilities always had HAZLOCs marked by barriers and/or colored floor striping, as well as signage. On one side of the line, you were NOT in the HAZLOC, but as soon as you stepped over the floor line, rope/cable/chain, or passed through the door, you knew you had entered the HAZLOC. These markings were critical in managing our HAZLOCs, especially for on-site contractors. Without these markings, it is usually easy to find safety concerns on how the HAZLOCs are managed, from improper equipment installed to workers using improper tools/equipment in the areas.

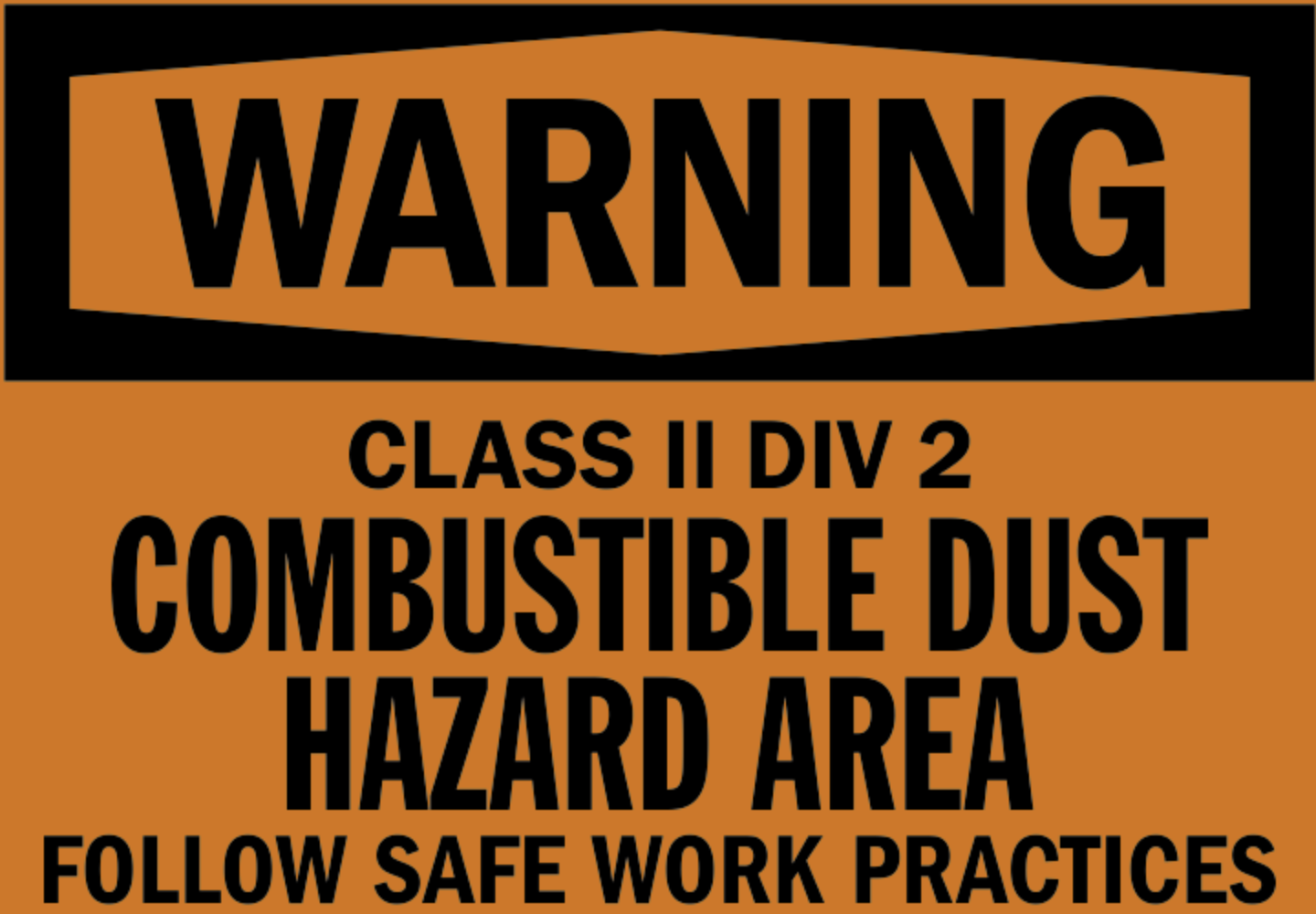

These signs/markings need to be more than just a painted line or a rope/cable/chain; we need to specify the area’s actual classification clearly: