SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

April 23, 2021

In a recent FaceBook Group posting, a member asked about using one of the DOT Special Permits that allows DOT containers/cylinders that came with a 15-year service life to have their service extended to 30 years. I wrote about this very issue in September 2019, explaining the pitfalls of using one of these DOT Special Permits. Bottom line is that DOT allows the cylinders to be re-certified...

Read More

April 22, 2021

The only item remaining in dispute is Item 3b of the citation. Item 3b alleges a violation of 29 CFR 1910.146(c)(4) for failure to develop and implement a permit-required confined space program to control entry of employees into the Fish Bin Chiller Alley at the Seward plant.

This item was classified as a serious violation with a proposed penalty of $975.

FINDINGS OF FACT

On September 7-8, 2000, Department...

Read More

April 22, 2021

OSHA has updated their COVID Frequently Asked Questions (FAQ) with the addition of three (3) new Q and A’s regarding COVID vaccinations and recordability related to adverse reactions to the vaccine:

…

HomeRead More »

Read More

April 21, 2021

I have written many articles on “scrubbing NH3” in preparation for line breaks/equipment openings or emergency removal from a compromised container and with NH3 the scrubbing media is simply water (H2O). I learned these “scrubbing” methods while working one summer in an internship and the safety pro who hired me was also an MSU graduate and he called these simple, yet...

Read More

April 21, 2021

Chlorine (Cl2) has a great warning property in that most people can smell Cl2 at around 0.002 ppm in the air (the official odor threshold per Agency for Toxic Substances and Disease Registry) and 0.31 ppm in water; although most data says its odor threshold is 0.2 – 0.4 ppm. In other words, even the most minute leak will be detected by most humans – that is if your process is not...

Read More

Why can't I pressure my piping and hold it for X hours and if no loss in pressure it passes my test?

April 21, 2021

This is a common question we get regarding pressure testing and leak testing of process piping. I have written quite a few posts regarding the ASME B31.3 and 31.5 requirements for pressure and leak testing over the years, but this question about holding pressure for 24-hours is one that just will not die. I am not here to say this practice is wrong, I’m just saying it is not one that...

Read More

April 21, 2021

Most of my clients who are users of Chlorine (Cl2) use it in vacuum systems where the Cl2 is being injected or inducted into a water flow. In these smaller “processes” it is not unusual to find “tubing” being used vs. hard pipe. It took me years to accept the tubing design model as I was always raised that Cl2 is a Category M Hazardous Material per AMSE B31 and thus...

Read More

April 21, 2021

I have asked for an official interpretation on this question, but until that arrives I will answer this question as I did for a client this week. Here is the scenario:

There is a significant fire in the RMP covered. The fire does NOT cause a release of the EHS, much less get off-site.

However, out of an abundance of caution, the local emergency response agency (Police, Fire, Sherriff,...

Read More

April 20, 2021

This is a fascinating case, as the OSHRC has upheld this citation, although they significantly reduced the $ and made it “other-than-serious.” But again, I disagree with this case, as the workers appeared to have been protected during the belt change; they did not follow the LOTO procedure, which I believe was “lazily written.”

This case boils down to a sprawling multi-component...

Read More

April 18, 2021

OSH ACT of 1970 Section (5)(a)(1): The employer did not furnish employment and a place of employment which were free from recognized hazards that were causing or likely to cause death or serious physical harm in that employees who performed hydrostatic testing were exposed to struck-by hazards due to the lack of specific testing procedures and training necessary to ensure personnel protection.

…...

Read More

April 13, 2021

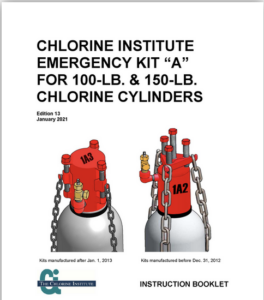

The Chlorine Institute has updated its instruction booklet for applying an A Kit to 100-LB. & 150-LB. Chlorine Cylinders. Remember, these Instruction Booklets can be downloaded for FREE from their bookstore and if your facility is using 100 or 150 pound Cl2 cylinders, the A Kit is a MUST HAVE and training on the proper application of the kit to the cylinder is CRITICAL to containing a leaking...

Read More

April 12, 2021

Many safety management systems are initially developed in a theoretical environment or for ideal situations with implicit and explicit assumptions about the system’s optimal performance, equipment, and human activities. This is often called WORK-AS-IMAGINED and is formally documented in training, procedures, and equipment operating manuals. Differences between the designed performance or WORK-AS-IMAGINED...

Read More