SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

February 19, 2021

Years ago, WorkSafe British Columbia (BC) put out a really nice video about a fatality caused by a worker welding on a used Acetone Drum. Although the video states the drum is a 44-gallon drum, it is in fact a 55-gallon drum. 44 imperial gallons is equal to 52 US gallons – which we call a 55-gallon drum. But what caught my attention back then (2012) was how WorkSafe BC explained...

Read More

February 19, 2021

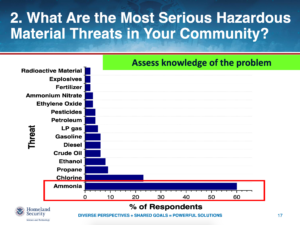

The Year 2020 was a trying time, but some exciting news has come out of 2020… Jack Rabbit III is in the works. The Cybersecurity & Infrastructure Security Agency (CSIA) and the Department of Homeland Security (DHS) have been working on the infamous Jack Rabbit study Phase III since early 2020. Without question, these Jack Rabbit studies/testing have been the largest-scale chemical...

Read More

February 19, 2021

Respondent is the owner and/or operator of the Facility and has developed an RMProgram accidental release prevention program for the Facility. On July 23, 2019 – July 25, 2019, the EPA conducted an on-site inspection of the RMProgram related records and equipment for the purpose of assessing the Respondent’s compliance with the RMProgram requirements and the implemented recognized and generally...

Read More

February 17, 2021

The major hazard involved with transferring flammable liquids is static build-up due to charge separation with the potential for discharge resulting in fire and subsequent loss of containment. Certain non-polar liquids can be charged while flowing through piping. Detectable and hazardous charges must be expected if the specific resistance of the liquid exceeds 108 ohms.

The potential for accumulation...

Read More

February 17, 2021

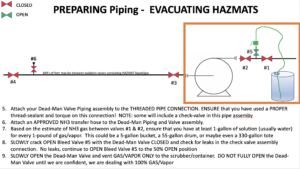

One of the most hazardous tasks that take place within a chemical process is the NON-Routine Opening of the process. And sadly, there are no RAGAGEPs or OSHA standards that establish minimum safeguards for such hazardous activities. Which I guess in some ways, is better as it has allowed the industry to establish some really nice safety practices for these activities. This presentation...

Read More

February 17, 2021

As we have discussed before, several years ago a governor of the great state of Washington passed a bill that required all the state’s codes and standards to be written in “everyday language” and oh how I love this approach. Even career safety professionals can struggle to try to decipher what Federal OSHA is really saying in their standards and we are still debating standards...

Read More

February 16, 2021

If you’re at a facility where the PSM-covered process involves ammonia refrigeration, OSHA has a few specific questions that would like to ask! These questions are specific to ammonia refrigeration facilities and will be used to evaluate a facility’s readiness to join the world-class ranks of VPP STAR workplaces. How would you fare with these ammonia refrigeration specific questions,...

Read More

February 16, 2021

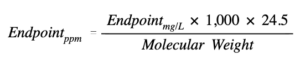

How well do you know your RMP chemicals? I mean really know them. One of the top questions we have received in the past several years is asking about the RMP chemicals’ toxic endpoints and why EPA uses mg/L instead of ppm. PPM is a volume-to-volume or mass-to-mass ratio, whereas mg/l is a mass-to-volume relationship. We can convert from mg/L to ppm pretty easily, using...

Read More

February 15, 2021

Almost every safety professional on the planet that works with chemicals, emergency response, and confined spaces knows that the Immediately Dangerous to Life and Health (IDLH) exposure is a game changer! But so many also struggle with what it means to actually work in an IDLH atmosphere. In this article, I want to try and explain what it means to respond to an UNCONTROLLED release of a...

Read More

February 14, 2021

I was having your run-of-the-day safety conversation with one of my favorite former OSHA safety engineers and he was quick to point out that one of my articles was not technically “compliant” with OSHA’s 1910.146 requirements when it came to the means we can use to isolate a Permit-Required Confined Space (PRCS). The means he took issue with was my reference to what is called...

Read More

February 14, 2021

Most of us know that a properly designed and installed ventilation system is our FIRST option for controlling hazardous concentrations of flammable vapors, gases, fumes, mists or dust, and volatile or airborne materials posing a health hazard, such as toxic or corrosive materials. And thankfully, most workstations and areas that need proper ventilation have it these days; however, we tend to...

Read More

February 13, 2021

A hazardous exhaust system shall be required wherever operations involving the handling or processing of hazardous materials, in the absence of such exhaust systems and under normal operating conditions, have the potential to create one of the following conditions:

…

HomeRead More »

Read More