SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

May 19, 2020

These were found as I was doing a design spec for a new NH3 Supply Business. These items are directly from the owner’s manual and were presented to the engineering firm after a “debate” on the reliance on Excess Flow Valve(s). These are about the three best manufacturer’s rules for EFVs I have ever seen! When so many companies are going weaker in their spec’s...

Read More

May 15, 2020

Our friends to the North have once again outdone themselves with an Emergency Response Task Force that developed two (2) new charts to aid in large scale-high hazard responses, such as a High-Hazard Flammable Trains (HHFT) incident. You can read the entire DOCUMENT ( A MUST READ for ALL responders – ESPECIALLY OFFICERS who may fill the IC role during such an incident). This document...

Read More

May 14, 2020

We have discussed the requirements for welder certification and their documentation, pressure and leak testing and its documentation, but the one area that I have not covered yet is the documentation of the Welding Inspector(s). As we have said, the certified (“coded”) welder makes the weld(s) and then BEFORE any testing, a certified welding inspector will perform an inspection of...

Read More

May 14, 2020

INCIDENT OVERVIEW

An ammonia release resulted in the temporary shutdown of an ammonia plant in an industrial food processing facility.

Ammonia refrigeration systems are designed to operate at 250 pounds per square inch gauge (Psig). The major components of the system like compressors, evaporators, liquid receivers, piping, and fittings, etc. are installed in a machinery room. The compressor sucks refrigerant...

Read More

May 14, 2020

DESCRIPTION

Ammonia compressor seal failure

INCIDENT OVERVIEW

An intermittent compressor shaft seal leak resulted in multiple ammonia releases which activated low level (<50 ppm) ammonia detector alarms.

The premises were not evacuated as the release was contained in a well ventilated mechanical room and the detector did not initiate a high-level evacuation alarm.

…

HomeRead More...

Read More

May 14, 2020

DESCRIPTION

Kraft paper pulping, strong black liquor was sprayed onto buildings and equipment.

INCIDENT OVERVIEW

Erosion of a stainless steel pressure piping elbow located on top of a black liquor storage tank resulted in strong black liquor being sprayed onto buildings, equipment, and the and surrounding area.

INVESTIGATION CONCLUSIONS

Black liquor is the by-product of the Kraft pulping...

Read More

May 14, 2020

DESCRIPTION

Failure of the main shaft seal ( mechanical seal ) of compressor #2 released ammonia vapor from the refrigeration system into the machinery room.

INCIDENT OVERVIEW

There was an ammonia leak from the main shaft seal, isolated to compressor #2 in the machinery room.

INVESTIGATION CONCLUSIONS

…

HomeRead More »

Read More

May 14, 2020

Damage description: Compressor valve packing failed to maintain a seal to prevent fluid escape.

INCIDENT OVERVIEW

Ammonia saturated oil leaked from the two-way valve packing of a compressor into the machine room.

The ammonia gases escaped from the leaked oil and triggered the machine room ammonia detector.

…

HomeRead More »

Read More

May 14, 2020

INCIDENT OVERVIEW

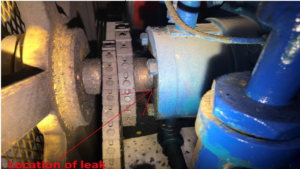

A hairline crack formed in a suction header pressure gauge line resulting in a minor leakage of ammonia.

INVESTIGATION CONCLUSIONS

The suction header pressure gauge line in question was ¼ inch steel tubing which connected the ammonia suction header to the pressure gauge installed in front of the engineer’s control room so that engineer on watch can visually monitor the pressure in...

Read More

May 14, 2020

Have you ever wondered where all the “separation distances” we see in OSHA Standards, NFPA Codes, Fire Codes, etc. come from? Who came up with them, what are they based on, etc.? All legitimate questions and you are NOT alone!! Many of these requirements have historical undocumented origins. Guidance, which may inform a sound technical basis for adjusting these distances,...

Read More

May 14, 2020

Anyone who has attended one of my Process Safety training courses has heard me use the phrase “circuitizing your piping” when we discuss the mechanical integrity aspect for piping. API 570 is our baseline RAGAGEP for our Piping Inspection Program, but API 574 is how these inspections will actually be conducted and this standard is chock full of great information and is a MUST READ...

Read More

May 13, 2020

Respondent is a municipality in the Commonwealth of Virginia. According to information provided to EPA, a release of chlorine gas, (CAS # 7782-50-5), occurred at the Facility on October 19, 2017, at approximately 11:40 a.m. due to a rupture of tubing connected to a chlorine tank in the chlorine room. On December 12, 2018, EPA representatives conducted an inspection of the Facility following the Release...

Read More