Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

August 18, 2024

It is suggested that LATENT ORGANIZATIONAL failures are analogous to the “resident pathogens” within the human body, which combine with external factors (stress, toxic agencies, etc.) to bring about disease. Like cancers and cardiovascular disorders, accidents in complex, defended systems do NOT arise from single causes. They occur through the unforeseen (and often unforeseeable) concatenation...

Read More

August 17, 2024

This EPA CAFO has me wondering who upset the U.S. EPA. There are only two (2) violations; one is the most cited RMP violation in the past seven years and is quite minor; the other was one of the newest RMP requirements, and those two violations netted a $93,000 citation. Respondent is the owner and operator of a facility that operates a refrigeration process that uses Anhydrous Ammonia in quataties...

Read More

August 16, 2024

On May 6, 2021, the Environmental Protection Agency (EPA) published a Final Rule listing R‒452B, R‒454A, R‒454B, R‒454C, and R‒457A as acceptable substitutes, subject to use conditions, for use in residential and light commercial air conditioning and heat pumps. These refrigerants are flammable and are classified as belonging to ANSI/ASHRAE Standard 34 safety group A2L. The listed substitutes are refrigerant...

Read More

August 16, 2024

A few weeks ago, I gave a sneak peek at what was coming: Manufacturer’s Limitations of Sulphur Sticks. Today, it arrived in the form of an OSHA LOI. A sulfur stick is a tool used to find ammonia gas leaks. Sulfur sticks, when burned, react with ammonia gas to make a visible smoke and are generally used near process equipment and piping to detect leaks. The company has an established procedure...

Read More

August 16, 2024

Does all fixed/portable/mobile equipment that is installed or enters a Hazardous Location (HAZLOC) have to be “certified” and “labeled” as being acceptable for that specific HAZLOC? The blunt answer is YES! But in today’s working world and global economy, I am seeing a lot of foreign approvals for electrical equipment that is not by one of OSHA’s NRTLs. I am also,...

Read More

August 16, 2024

As I have said for years, we may never know where the nasty rumor came from that installing threaded and/or flanged piping is easier and cheaper than welded pipe. That is a “pipe dream”… LOL see what I did there? For example, did you know that if the piping will be pneumatically pressure tested, then ASME B31.3/.5 requires that ALL threaded, bolted, and other mechanical joints…...

Read More

August 16, 2024

One of the significant deficiencies we find in our audits/investigations is the lack of meeting ASME B31.3/.5 to install process piping. I have written about this topic for decades, and I still get inquiries monthly about this standard and its critical role in real process safety management. For those who attend my 5-day Advanced PS Course, this single topic gets more questions/discussion than any...

Read More

August 15, 2024

Those of you who practice in the Process Safety arena are well aware of OSHA’s and EPA’s requirements to have “written procedures to maintain the on-going integrity of process equipment.” (1910.119(j)(2). However, OSHA and EPA also have a section in their Mechanical Integrity elements titled “Quality Assurance.” 1910.119(j)(6) Quality assurance. 1910.119(j)(6)(i)...

Read More

August 15, 2024

Most safety professionals are well aware of the many medical evaluations called out in OSHA standards, such as the medical evaluations for workers wearing respirators, emergency responders, etc. But we also have a medical evaluation requirement in Process Safety Management that plays a critical role in our piping Quality Assurance (QA) program. When using either ASME B31.3 or 31.5 to design,...

Read More

August 14, 2024

I see severe risk-taking regarding “safety assumptions” in process safety in my travels. I guess I am just “old school” and believe that every Pressure Vessel (PV) deserves its very own Pressure Relieving Device (PRD). But in today’s economy, where “costs” can be a driver in decision-making, I have experienced numerous scenarios where a single PRD will be “assumed”...

Read More

August 13, 2024

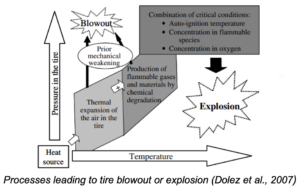

Overview: A tire blowout occurs after the mechanical failure of the tire or rim assembly at pressures typically around 145 psi. Tires exposed to heat may undergo the process described below and violently explode. Explosive Process: There are three (3) phases leading to a tire explosion: 1. Air pressure inside the tire will rise from 90 to 235 psi as temperatures rise. 2. At approximately 365⁰ Fahrenheit,...

Read More

August 13, 2024

The Respondent owns and operates a bleach manufacturing facility, which operates a bleach manufacturing process (the Process) and maintains a maximum chlorine inventory greater than the threshold quantity of 2,500 pounds. The Process is subject to OSHA’s process safety management standard, 29 C.F.R. § 1910.119, because the Process involves greater than the threshold quantity of 1,500 pounds of...

Read More