Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 19, 2024

I have written several articles on the topic of when we store our flammable liquids BELOW their flash points with the aid of refrigeration and how that makes our “refrigeration/chiller” a critical utility if we wish to take credit for storing the flammable below its FP. I have also discussed processing a Class IIIB/Cat 4 flammable liquid within 30 degrees of its FP. However,...

Read More

April 19, 2024

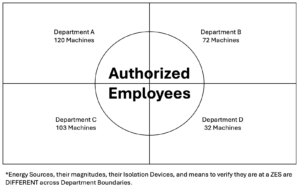

Managing our LOTO program requires considerable resources, and it requires a team approach! However, we see many failed attempts to control hazards through a facility’s LOTO program. One of the most common failures is how “authorized employees” are defined in terms of the skills they are trained on. Which Rabbit Hole you choose to go down and how far you go down depends on the...

Read More

April 19, 2024

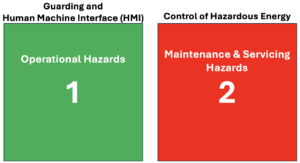

I put this image together for a friend struggling to demonstrate to their management that we can not discuss LOTO until Machine Guarding is in place. These two topics go hand in hand and trust me; if there are guarding issues, those hazards will be compounded when we attempt to frame up the LOTO program. Guarding is for the OPERATIONAL safety of the machine/equipment and, if not done well, poses a...

Read More

April 16, 2024

An Ohio subsidiary of one of the world’s largest automotive suppliers could have prevented a 26-year-old employee in Franklin from being fatally crushed in October 2023 if the company had provided proper machine guarding. OSHA responded after being informed of the incident and learned the worker, on the job for about a year, was placing cardboard under a machine that bends vehicle exhaust pipes...

Read More

April 13, 2024

Are you tired of playing the OSHA Compliance game that requires us to “comply” with standards that are 50 years old? The International Fire Code (IFC) is an excellent resource for taking your hazardous materials handling systems/processes to the next level. The IFC is used or adopted in 42 states, including the District of Columbia, Guam, Puerto Rico, and the U.S. Virgin Islands....

Read More

April 12, 2024

There are two (2) types of Asphyxiants:

Simple

Chemical also known as Systemic

These different types of asphyxiants behave differently and cause harm differently.

…

HomeRead More »

Read More

April 12, 2024

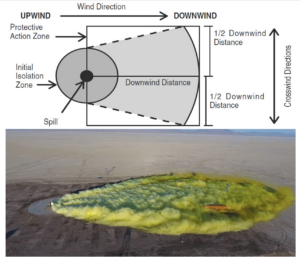

Chlorine is EXTREMELY HAZARDOUS, with an IDLH of 10 ppm and a TLV of 0.5 ppm (just above the odor threshold for most). Chlorine is heavier than air (VD > 2.5), and when released, it forms a greenish-yellow gas with a pungent, irritating odor that follows the terrain at ground level. The mean odor threshold for chlorine lies between 0.2 and 0.4 ppm. Chlorine is a NON-FLAMMABLE gas; however,...

Read More

April 12, 2024

An image from my HAZMAT courses…

People wonder why the ERG Protective Action Distance diagram is shaped like it is. This image validates the model…

NOTE: Cl2 release image is from the Jack Rabbit testing project

Read More

April 12, 2024

Here is a GREAT “self-assessment” tool, just eight (8) questions, to evaluate your facility’s ability to investigate and perform causal analysis properly.

…

HomeRead More »

Read More

April 12, 2024

This is a crazy case! The mill hired a contractor to build scaffolding inside one of its Chlorine Dioxide (CLO2) tanks. The mill prepped the tank and even performed the initial air sampling of the space. Turned it over to one of the scaffolding contractor employees who would be the attendant for the entry. Three entrants and the attendant were wearing personal Cl2 air monitors. ...

Read More

April 12, 2024

As he had many other days, the morning shift welder arrived at 5 a.m. to work on Aug. 28, 2023. Tasked with doing some fabrication work in a 4-foot by 8-foot space in a ship’s hull, the employee began work unaware that fatal suffocation would soon end his life. Less than two hours after entering the ship, a supervisor found the unconscious welder and signaled for help, only to fall unconscious as well....

Read More

April 11, 2024

The Emergency Planning and Community Right-to-Know Act (EPCRA) requires businesses that store and/or manufacture, process, or use certain chemicals to complete the Tier II (EPCRA 311 and 312) Report and/or the Toxics Release Inventory (EPCRA 313) Report, also called the Form R. Section 112(r) of the Clean Air Act focuses on risk management for accident prevention. While these three (3) programs have...

Read More