Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 13, 2011

OSHA has a long and consistent history of interpreting its standards and other requirements to require employers to present information in a manner that their employees can understand. See, e.g., CPL 2-2.38(D)(1998) (“[i]f the employees receive job instructions in a language other than English, then training and information to be conveyed under the [hazard communication standard] will also need...

Read More

April 13, 2011

Paragraph (c) of 29 CFR 1910.151 requires that suitable facilities for quick drenching or flushing be provided within the work area for immediate use if an employee’s eyes or body may be exposed to corrosive materials. The OSHA standard does not set specifications for emergency eyewash and shower equipment, but we agree that equipment that complies with ANSI requirements would usually meet the...

Read More

April 13, 2011

MultiVapor is a computer tool for estimating breakthrough times and service lives of air-purifying respirator cartridges manufactured to remove toxic organic vapors from breathed air. It can also be used for larger filters and for carbon beds of any size prepared for laboratory studies. MultiVapor replaces the program, Breakthrough, which performs the same function for only one organic vapor at all...

Read More

April 11, 2011

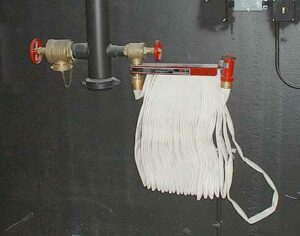

If you have ever walked the stairs of a highrise building or the halls of a large hotel you have seen a “Standpipe System”. Many industrial facilities have these systems in place as well. In fact some state fire and building codes REQUIRE these systems be “installed”. Notice I emphasised “installed”, as most were installed, but have not been maintained,...

Read More

April 11, 2011

One of EPA’s most often cited issues with a facilities Risk Management Plan (RMP) revolves around “updates to the plan”. Most, but not all, know that the plan has to be updated every five years; but did you know there were other triggers that require a RMP to be updated more often than every five years. Here are the changes that would REQUIRE an UPDATE to an RMP: …...

Read More

April 11, 2011

Does your facility have a standpipe system? Does the facility test the hoses and nozzles on these systems annually? Does the facility inspect them montly? BEFORE I even say anything, let me say my DISCLAIMER…check with your local fire department(s) AND your property conservation insurer BEFORE you remove the first hose or nozzle! Now that I have said that, you will want to do...

Read More

April 11, 2011

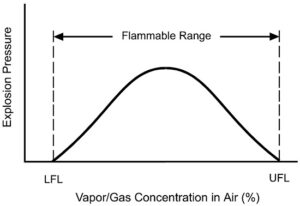

In this article I would like to lay the foundation for future discussions on one of my favorite topics…Flammable Liquids. I will try to explain flammable liquids at their very basic level. There is MUCH MORE to learn about flammable liquids, but this will get us off to a good start with the fundamentals. Let’s start by discussing the term Flash Point. We could say...

Read More

April 10, 2011

We are never quite sure how these myths get started, but my team and I hear some doosee’s from time to time. The “myth” I am going to discuss today is one we actually see more often than not. We see this even in facilities that have a good grasp of their Hazardous Locations and of course we see it most often in facilities that are struggle with classifying thier hazardous...

Read More

April 10, 2011

Most of us know that OSHA requires us to retain our canceled PRCS Entry permits for one year to be able to do our annual review of our program, which is also an OSHA requirement. However, and this is a HUGE “however,”…if the permit’s air monitoring section shows there was any exposure to a contaminant, that permit would fall under 1910.1020 retention requirements (e.g.,...

Read More

April 10, 2011

Anyone who has been involved in incident investigations will just smile and feel a lot of relief that your world is not so different than the safety professional down the street! Although the video is slanted toward a QC type investigation, you will be able to relate to the LAME _ _ _ _ corrective actions in this “Top Ten List of Unacceptable Corrective Actions“. See if you...

Read More

April 10, 2011

On June 20, 2009, an ammonia line ruptured during maintenance at a poultry processing plant in Robeson County, N.C., killing one employee and injuring several others. This accident should remind employers of the hazards associated with the use of anhydrous ammonia as a refrigerant at food processing plants. Click Here (.pdf) to see and print this 2-page Alert. If you have NH3 on site, this is...

Read More