Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

March 12, 2024

Yes. OSHA’s standards at 29 CFR § 1910.212 and 29 CFR § 1910.219 apply to the safeguarding of machines and mechanical power-transmission equipment and require guarding to protect the operator and other employees in the area from hazards such as those created by ingoing nip points, rotating parts, flying chips, and sparks. In regard to the gap dimension between belts and their respective guards,...

Read More

March 12, 2024

I am a proponent of accountability in safety; however, I also believe that accountability is necessary at all levels of the organization. We tend to be very quick in identifying the ACTIVE failures by those who made the error, mistake, or violation, and a negative consequence was the result (vs. all those times, the outcome was positive). Heck, in today’s world, we may even have caught...

Read More

March 11, 2024

Some of the more eye-opening revisions: Outlining STOP-WORK procedures in Program 3 employee participation plans A justification in the risk management plan is required when: hazard evaluation recommendations are NOT adopted facility-siting hazard recommendations are NOT adopted Safer Technology Alternatives Analysis (STAA) recommendations are NOT adopted third-party compliance audit recommendations...

Read More

March 11, 2024

DOT/PHMSA have compiled the most important changes from ERG2020 to ERG2024, organized by the color of the corresponding section in the guidebook White Yellow/Blue Orange, and Green In addition to the changes listed below, all sections have undergone minor editorial changes for accuracy and consistency. In this edition, DOT/PHMSA has added QR codes to the back cover of the hard copy version of...

Read More

March 11, 2024

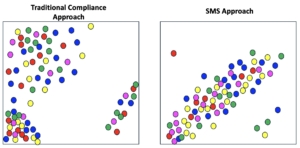

One of the top questions I get from “cold callers” or those who have joined SAFTENG and have digested my 400+ articles on Safety Management Systems and all their elements is: So, what does an SMS do for me and my facility? The best way to explain this is by an old scatter chart I had done in 1995 by a consulting firm we hired to help us achieve OSHA’s VPP STAR level of safety. ...

Read More

March 10, 2024

NOTE: I have never managed a facility/workforce where we required Hi-Vis garments, except for Fire Watches and PRCS Entry Attendants, but those requirements were not for the user’s safety, so we did not get into all the ANSI requirements for these vests. However, I do equate this Hi-Vis effectiveness concern to what I dealt with regarding Flame Retardant Clothing (FRC) and its continued effectiveness. ...

Read More

March 10, 2024

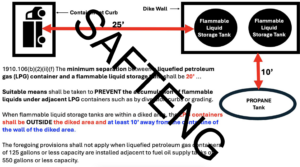

This is another opportunity for facility sitting to apply specific metrics to the exercise. Just as the distances for Tank Truck and Rail Car Unloading/Loading facilities are intended to protect our bulk storage tanks, this is intended to prevent BLEVE(s) that could impact the above-ground storage tank. (emphasis by me) 1910.106(b)(2)(ii)(f) The MINIMUM SEPARATION between a liquefied petroleum gas...

Read More

March 10, 2024

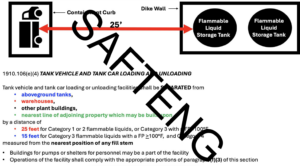

In some cases, we can actually put specific measurements in our “facility siting” analysis. Take, for example, an old but often missed distance between the tank truck/railcar and the closest aboveground tank. (emphasis by me) 1910.106(e)(4) Tank vehicle and tank car loading and unloading. 1910.106(e)(4)(i) Tank vehicle and tank car loading or unloading facilities shall be separated...

Read More

March 10, 2024

At 7:30 p.m. on July 2, 2021, Employee #1, Employee #2, and Employee #3 performed two maintenance tasks in the M2 crude rectification section on the ground and second levels at tower M2-T250 and vessel V-207. On July 2, 2021, during the night shift, three (3) gas monomer chemical operators were exposed to toxic fluorocarbons and other hazardous chemicals while performing the maintenance tasks at M2-T250,...

Read More

March 9, 2024

We often refer to the ABC Model when discussing “Behavior Based Safety.” ABC stands for Antecedent ⇒ Behavior ⇒ Consequence An antecedent comes before a behavior and may trigger that behavior. A behavior is what/how the individual does an action. (good or bad). A consequence is something that follows the behavior (good or bad). So, an OSHA citation could be considered a “consequence”...

Read More

March 9, 2024

The Facility uses, handles, and/or stores more than a threshold quantity of ammonia (anhydrous), ammonia (concentration 20% or greater), and chlorine, which are regulated substances, as specified at 40 C.F.R. §§ 68.115 and 68.130. The Facility’s Cooling Tower 2 chlorine injection area contains up to 4,000 lbs of chlorine in two (2) 1-ton cylinders, above the chlorine RMP threshold quantity of 2,500...

Read More

March 8, 2024

A Health and Safety Executive (HSE) investigation into a gasoline overfill of a carbon adsorption vapor recovery unit (VRU) revealed concerns with the VRU’s design. The overfill prevention system was NOT INDEPENDENT of the basic process control system (BPCS). When the BPCS failed, the overfill prevention system also failed. This resulted in loss of containment, and risked a significant...

Read More