Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

January 30, 2024

I am teaching my 3-Day Intermediate Process Safety course this week, and one of the popular exercises we do on Day 1 is the “Vehicle Safety Challenge.” It is designed to teach students to begin thinking about Layers of Protection within the PREVENT-PROTECT-MITIGATE model. Five students in four (4) groups have 15 minutes to

…

HomeRead More »

Read More

January 30, 2024

The good old “safety incentive program” has been around since man walked upright and has been misleading management since its conception. The concept is valid, based on the old “carrot and the stick” model. There has always been one fatal flaw in these programs… they usually incentivize the WRONG things! The traditional safety incentive programs, many...

Read More

January 30, 2024

One of the top questions we get regarding contractor safety is, “Do I have to evaluate, orientate, and audit subcontractors working for a contractor we hired?”.

OSHA’s latest revision of their PSM CPL answered this question.

Is the host employer of a PSM-covered facility responsible for the safety of subcontractors?

…

HomeRead More »

Read More

January 30, 2024

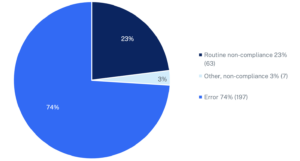

The NSW Resources Regulator has published a fact sheet on its human and organizational factors data review. The Regulator engaged the Keil Centre to independently review its human and organizational factors analyses over the past five (5) years, where HUMAN ERROR and DELIBERATE NON-COMPLIANCE played a role in incidents. The review looked at 267 incidents at 180 at surface mines and 87 at...

Read More

January 30, 2024

Responding to a report of workers being exposed to anhydrous ammonia, federal investigators found a Madison ice cream plant lacked sufficient process safety management procedures to control the release of hazardous chemicals. Investigators with the U.S. Department of Labor’s Occupational Safety and Health Administration determined the Ice Cream facility failed to document that equipment was being...

Read More

January 30, 2024

On December 14, 2023, OSHA published its revised Compliance Directive for Process Safety Management standard 1910.119, effective January 26, 2024. This new version is in Q7A format and was done nicely, although there are a number of things in the answers that I am sure will be challenged. I have highlighted some of the interesting (albeit I believe the correct answer). For example, QA-31...

Read More

January 30, 2024

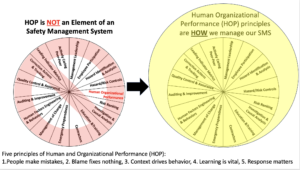

HOP is NOT an Element of a Safety Management System (SMS) HOP principles are HOW we manage our SMS We see a lot of discussions on social media regarding the role of HOP and Psychological Safety, two methods I fully embrace should be used in OSH and PSM. However, I view these two methods as HOW I manage my safety management system (SMS), and they do NOT replace my SMS (as some “experts”...

Read More

January 29, 2024

Let’s talk about DE-incentivising businesses to properly manage Occupational Safety and Health (OSH), even at the most basic level. OSHA now requires businesses to report their injury and illness logs, which they will use to identify workplaces needing a compliance inspection. They are doing this due to their lack of adequate resources, and they want the businesses and industries to self-report...

Read More

January 29, 2024

Sweating the “small stuff” matters in process safety management. Meeting the details of our chosen RAGAGEPs matters! Although I am often told, “That is a picky audit finding,” it is what it is. Far too many facilities believe that designing their process piping to be bolted flange assembly vs. welded joints is somehow easier; in some ways, it is more difficult. ...

Read More

January 28, 2024

We have discussed the critical role of “torque” in constructing our chemical processes. I catch a lot of flack for my insistence on this critical function, for which I am genuinely surprised. But our piping design and construction RAGAGEP (ASME B31.3) is pretty clear on the matter, and now OSHA and EPA have “caught on” and are issuing citations where there is an...

Read More

January 28, 2024

The refrigerant in this accident is R-32 (Difluoromethane), described as ” a colorless, odorless, mildly flammable gas. “Its ASHRAE rating is A2L, making it a CAT1B flammable gas if OSHA adopts Rev. 7 of the GHS this year. These A2L “mildly flammable gases” are exempt from many of the requirements other flammable gases must meet (e.g., electrical classifications, mechanical...

Read More

January 28, 2024

Another pressuring test “gone bad”. I want to remind anyone who wonders how to DEFINE and QUANTIFY a “safe distance” when piping is being pressure tested, especially when that test is a “pneumatic” test. ASME PCC-2–2022, Repair of Pressure Equipment and Piping, Mandatory Appendix, 501-III, Safe Distance Calculations for Pneumatic Pressure Test is...

Read More