Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

December 9, 2023

What happened? The extinguisher, rated to 2900 psi was being tested to a pressure of 4351 psi. The incident occurred when the test pressure reached 2842 psi. The extinguisher was 13 years old. No one was harmed. The failure occurred under test conditions, and no personnel were nearby to be injured. The hydrostatic test was a scheduled 5-year test carried out as per the company’s planned maintenance...

Read More

December 9, 2023

NOTE: this was NOT a PSM covered process. OSHA determined the employee — on the job just two months — opened an air intake valve to inspect a noise coming from a barium sulfide wash cone with a steam line that was left open the day before. A rush of cold air in the steam line created a bubble that pushed up heated sludge onto the worker, causing fatal burns. A second worker suffered second-degree burns...

Read More

December 8, 2023

WAC 296-880-20005 Fall protection required at four feet or more

…

…

HomeRead More »

Read More

December 8, 2023

Lockout is a life-critical program/process/procedure(s). Our efforts to VERIFY that the program/process/procedures meet our needs is a CRITICAL path in the LOTO process. OSHA recognized this when it promulgated its Control of Hazardous Energy standard (1910.147). Specifically, 1910.147(c)(6) “Periodic Inspections” requires the employer to verify the program/procedures and that...

Read More

December 6, 2023

High-hazard Group H occupancies are characterized by an unusually high degree of explosion, fire, or health hazard compared to typical commercial and industrial uses. There is one common feature about Group H occupancies—they are designated as Group H based on excessive quantities of hazardous materials within the facility/building. Where the quantities of hazardous material stored or used in...

Read More

December 2, 2023

From “facility siting” in a PHA to establishing emergency “assemble areas,” the methodology we use matters. Many of us use a RAGAGEP from The European Industrial Gases Association (EIGA) titled Methodology for Determination of Safety and Separation Distances. The “safety distance” is to provide a minimum separation that will mitigate the effect of any...

Read More

November 30, 2023

Today the U.S. Chemical Safety and Hazard Investigation Board (CSB) released its final report on a flammable vapor explosion and fire at the Yenkin-Majestic facility in Columbus, OH, on April 8, 2021. One employee died during the incident, and eight other workers were injured. The CSB’s final report makes several important safety recommendations to Yenkin-Majestics, as well as to professional...

Read More

November 30, 2023

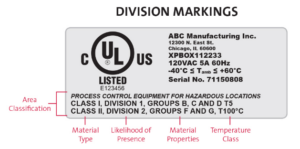

Recently, OSHA cited a global manufacturer for HAZLOC violations using its 1910.307 – Hazardous (classified) locations standard. We do not see this standard often cited, as in most PSM/RMP citations related to Hazardous Locations (HAZLOC), OSHA and EPA will reference the RAGAGEP NFPA 70. It is one of our common findings in our PSM/RMP audits at flammable processes; however, our findings...

Read More

November 30, 2023

A global manufacturer of industrial gas could have prevented a May 2023 explosion that severely injured several employees by following required operating procedures in the manufacturing process where diborane — a toxic, colorless, and pyrophoric gas — is produced, distilled, mixed, and transferred. OSHA determined the explosion occurred as a 25-year-old product technician used a heat gun to transfer...

Read More

November 28, 2023

Respondent is an “owner or operator” of the Facility, which produced, used, or stored anhydrous ammonia, a hazardous substance. On April 25, 2019, the EPA conducted an inspection to determine compliance with the Comprehensive Environmental Response, Compensation and Liability Act (“CERCLA”) Section 103, 42 U.S.C. § 9603, and the Emergency Planning and Community Right-to-Know Act (“EPCRA”) Sections...

Read More

November 28, 2023

Respondent has a semiconductor manufacturing process at the Facility. The Facility has three covered processes using silane, ammonium hydroxide (conc 20% or greater), and anhydrous hydrogen chloride, meeting the definition of “process.” Respondent has greater than threshold quantities of anhydrous hydrogen chloride, silane, and ammonia (concentration 20% or greater) in covered processes...

Read More