If I had a dime for everytime someone says to me… “where do you come up with all this sh_t?” during our deep discussions on process safety topics. And whenever I do my 5-day Process Safety course we seem to always get deep into the “process safety weeds” and one topic that many students are amazed by is that there is a RAGAGEP for just about all of our needs. The one task that we struggle to find guidance on is Line Breaking, but don’t worry too long, as we do have a RAGAGEP on what type of energy isolation would be acceptable for all sorts of work tasks. Those of us who have experience with isolating Permit-Required Confined Spaces (PRCS) will be familiar with Double Block & Bleed (DB&B) and Blinding/Blanking. I learned of this RAGAGEP while working on a Bromine design project at one of my former employers and was amazed at the level of the engineering review associated with “equipment isolation for maintenance and entry” the engineers were taking on – before the project was even funded! They were using a Norwegian Standard from The Norwegian Oil Industry Association (OLF) and The Federation of Norwegian Industry. The standard is NORSOK STANDARD P-001, Process Design, which contains an entire section on the “acceptable energy isolation” based on the risk. A really neat standard and it brings a lot of rationales when trying to decide if “single valve isolation” is acceptable or if the task needs “Double Block and Bleed isolation”. Check out the standard and give it some serious consideration if you’re looking for some concrete engineering logic behind your energy isolation needs.

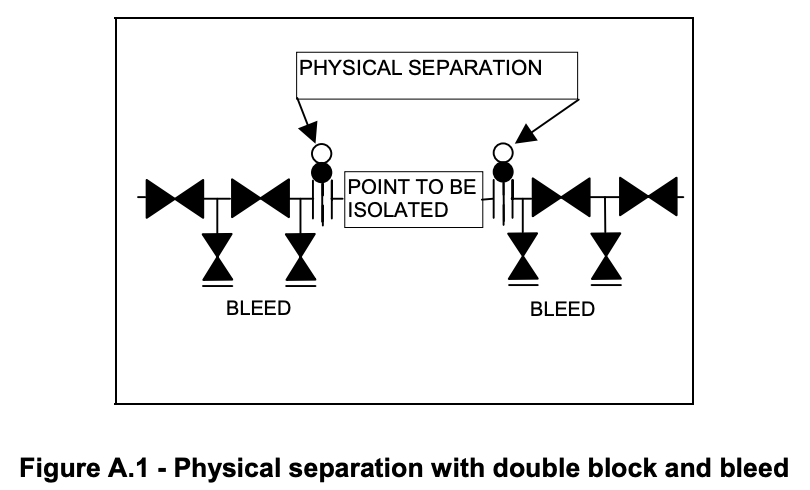

Process Safety – Systems and Equipment Isolation