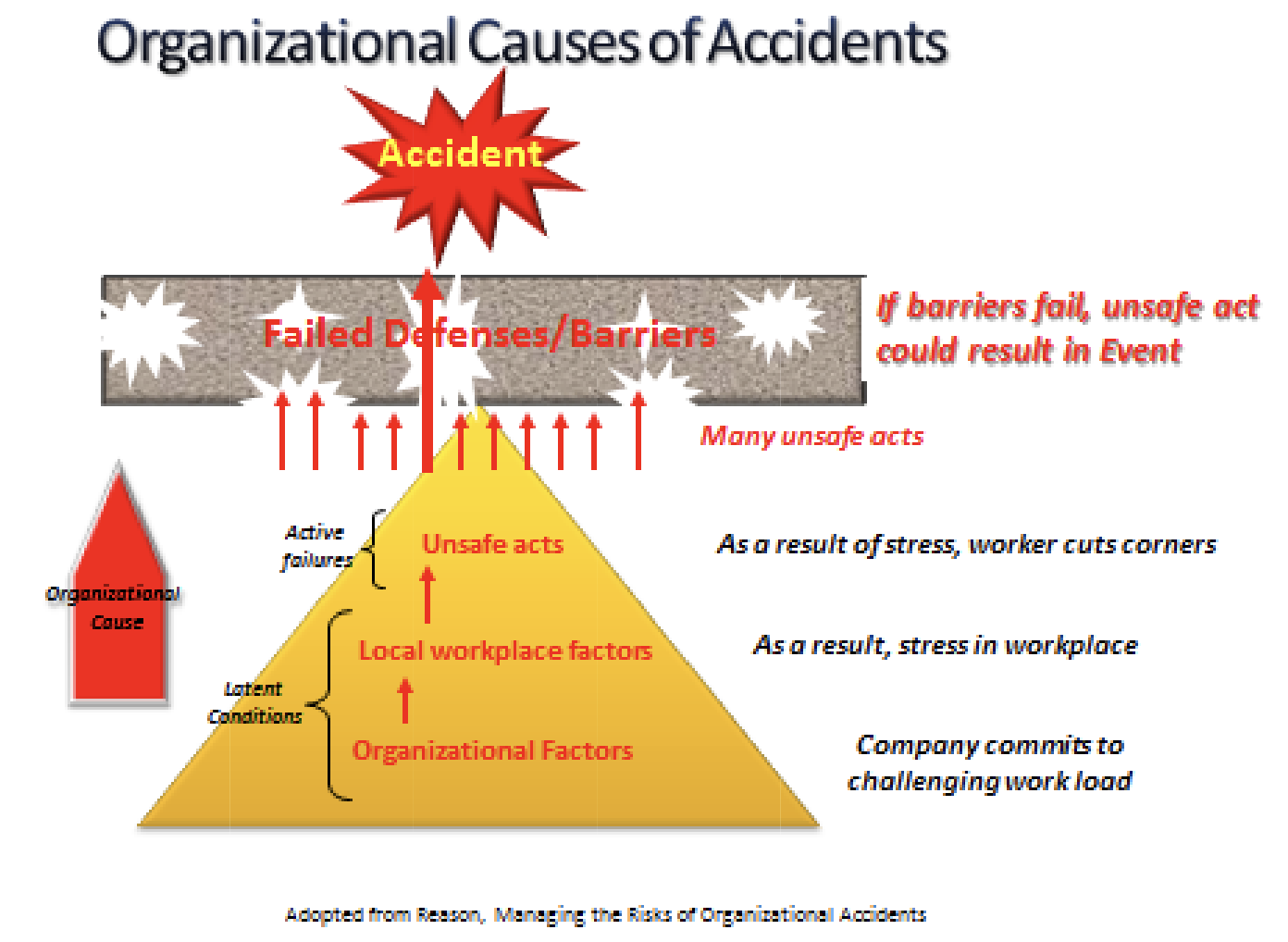

Yes, I am betting this same drum again. I believe in Reason’s SMS model, especially his Human Failure model of Errors, Mistakes, and Violations. This recent incident is a perfect example of management’s lack of understanding of SMS fundamentals and how LATENT ORGANIZATIONAL FAILURES result in horrible outcomes. Essentially, this is what happened:

An LOPC event occurred, resulting in a Reportable Release, which requires a written follow-up to EPA on the cause(s) and what will be done to address the event. This LOPC event occurred because an operator made a “mistake” due to the IMPROPER LABELING of a valve. But this was a critical mistake that sent the process into immediate upset conditions and the lifting of a PRD. The Emergency Shutdown procedure instructed the operators to close a Manual Shutoff Valve, which had they been able to do would have certainly reduced the release amount well below the RQ of the chemical involved. However, this Manual Shutoff Valve was about 20′ in the air, and access to this valve was not “readily available.”

Since this release would be “public knowledge” because it exceeded the chemical Reportable Quantity (RQ), the legal team felt the business needed to take swift and firm action against those involved in the event. This way, they could show they were serious about process safety to the “regulators” by taking these disciplinary actions. However, during our PSM/RMP audit about a year later, we came across this incident and all the compliance failures that went with it, and we were shocked to learn that two operators were suspended for 3 and 5 days without pay for “failure to follow procedures.”

Here is the back story of the LATENT ORGANIZATIONAL FAILURES…