CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

January 15, 2023

The rate of recordable injuries in the electric power sector has declined steadily over the past decade; however, the rate of serious injuries and fatalities (SIFs) has plateaued. Unfortunately, studying SIFs is a paradox. On one hand, SIFs are incredibly important and deserve significant resources for investigation. On the other, learning from these events and detecting causal patterns are challenging...

Read More

January 15, 2023

I have been driving for 46 years and I have never died in a car wreck – BUT I STILL WEAR MY SEATBELT! The mere fact there has not been a negative result from an act does NOT mean we can we should continue that act without some layers of protection! So when someone claims a job has been done for ____ years without injury, think about your seatbelt and the old saying “An ounce of prevention...

Read More

January 15, 2023

In the 2021 International Mechanical Code (IMC), the International Association of Ammonia Refrigeration (IIAR) was successful in simplifying the code requirements for refrigeration systems using Anhydrous Ammonia (NH3). The code now reads: 1101.1.2 Ammonia refrigerant Refrigeration systems using ammonia as the refrigerant shall comply with IIAR 2, IIAR 3, IIAR 4, and IIAR 5 and shall not be required...

Read More

January 15, 2023

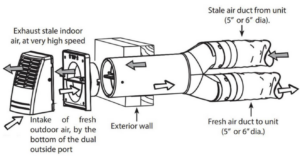

A new type of factory-built combination exhaust and intake air fitting is introduced that does not require separation between the two openings. Although this has been approved for the 2021 IBC, it is ONLY for dwelling or sleeping unit mechanical ventilation systems.

It is NOT ALLOWED for

HAZARDOUS MATERIALS

Exhaust Ventilation systems

Read More

January 15, 2023

I can not understand why the U.S. National Library of Medicine (NLM) is ending WISER. This single ER tool was undoubtedly the best available ER tool! I have been sharing it for at least the past 10 years in all my HAZMAT courses. It is indeed a SAD day; as of February 28th, 2023, NLM will discontinue the Wireless Information System for Emergency Responders (WISER), the website ( https://wiser.nlm.nih.gov)...

Read More

January 14, 2023

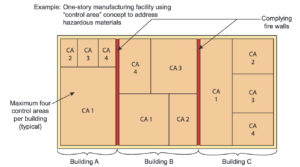

The 2021 International Building Code (IBC) has revised how firewalls can be used to establish “control areas” within a structure.

Section 414.2.3 Number states:

…

HomeRead More »

Read More

January 14, 2023

The 2021 international Building Code (IBC) has a new requirement that will impact EXIT doors and their exterior landings. Most states have NOT adopted this edition of the IBC, so this is just a heads up of what’s to come. The new section (1809.5 .1 Frost protection at required exits) states:

…

HomeRead More »

Read More

January 14, 2023

In the CSB’s final report on a refinery incident, the agency calls on OSHA to: Develop guidance documents for performing process hazard analysis on operating procedures to address transient operation hazards in facilities with Process Safety Management (PSM) covered processes. A PHA is a critical element of the process safety management system; unfortunately, we see more poorly performed PHAs...

Read More

January 13, 2023

It seems these signs have grown horns and arisen from hell! We have all seen them, and most of us have had them in our workplaces from time to time. But are they evil? Are they an accurate indicator of injury data manipulation? Celebrating our successes in safety is IMPORTANT, and there is no better metric to celebrate than an actual reduction in injuries to our team...

Read More

January 12, 2023

A Wisconsin company that supplies malt barley to major craft breweries, home breweries, and other spirit and food production in the Midwest has again been found exposing employees to dangerous workplace hazards by federal safety inspectors. OSHA has proposed penalties of $174,351 after inspectors identified two repeated and 14 serious safety and health violations after responding to a complaint...

Read More

January 11, 2023

MSA has a CBRN-certified Powered-Air Purifying Respirator (PAPR) for first responders; however, this PAPR is NEVER to be worn for the initial entry into the Hot or Warm zones!

This is not a SAFTENG requirement; this comes straight from OSHA’s (and EPA’s) HAZWOPER standard…

…

HomeRead More »

Read More

January 11, 2023

It is pretty standard practice to hook up a compressed gas cylinder to a process. In fact, many “blanket systems” on a small vessel will use a Nitrogen CG cylinder to provide the blanketing gas. However, it is even more common to find this setup done improperly. In this article, I will offer a RAGAGEP to follow that explicitly covers this practice. First things...

Read More