CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

January 8, 2023

Maybe I’m just old school, but is it just too much to ask for: a well-written safety procedure, one that is written and analyzed with a safety pro and the worker(s) who do the actual work, that management will fully support the procedures everyday-everytime, including on holidays that fall on a Sunday, and employees will follow procedures everyday-everytime, including on holidays that fall on a Sunday?...

Read More

January 7, 2023

An Emergency Escape Breathing Apparatus (EEBA) is NOT an SCBA and is ONLY permitted to be used to EVACUATE a hazardous atmosphere – NEVER to enter one, especially one within a Permit-Required Confined Space! On 1 April 2022, after completing the loading of coal cargo, the Singapore registered bulk carrier, Nozomi, was anchored at the Tanjung Api–Api anchorage, South Sumatera,...

Read More

January 7, 2023

What management thinks we are… Reality as to what we really are When it comes to creating a safety culture, most management teams think the safety leader has some kind of magic wand that they can wave and create the culture they want. When in reality, we are NOT culture builders! Culture comes from senior leadership – safety leaders help managers create the culture they want. ...

Read More

January 7, 2023

The latest International Mechanical Code (IMC) has gotten more particular in how our exhaust systems get their make-up air. 510.5.5 Makeup air is a new section that clarifies what we have discussed in the “design basis” of our ventilation systems…

(emphasis by me)

…

HomeRead More »

Read More

January 7, 2023

Another reason I like using the IFC over OSHA standards is that they take a lot of guesswork out of the safety equation! Take, for example, the following list of 42 specific locations where a fire extinguisher is required based on the hazard…

…

HomeRead More »

Read More

January 7, 2023

For several editions, the IFC has incorporated a “Performance-Based Design Alternative” to comply with the requirements of Part V—Hazardous Materials (Chapters 50-67). This was initially added so that facilities already doing PSM/RMP could show compliance with the state fire code without any additional work. In the 2021 edition of the IFC, this alternative has been expanded to include...

Read More

January 6, 2023

A video based on Don Merrell’s famous safety poem “I chose to look the other way”

Don Merrell

J.R. Simplot Company

Don Plant Training Center

…

HomeRead More »

Read More

January 6, 2023

Image Source The infamous LPG Cylinder Exchange “Cage”. Pull into any convenience mart/gas station these days and you will most likely see one of these cages. I have always claimed that these cages require Vehicular Barrier Protection (VBP) where they are in the path of vehicles and I still stand behind my position. But NFPA and the National Propane Gas Association have...

Read More

January 6, 2023

Most adults have seen Sky Lanterns in movies, and some of you may have even participated in their release. They are very popular at weddings, festivals, and memorials. But these devices pose serious fire hazards and are being banned by many local Authorities Having Jurisdiction (AHJ). They are essentially a paper hot air balloon with an open flame that drifts in the wind and eventually...

Read More

January 6, 2023

Respondent is the owner and/or operator of a facility that uses, handles, and/or stores more than a threshold quantity of ammonia (anhydrous), ammonia (concentration 20% or greater), and chlorine, which are regulated substances, as specified at 40 C.F.R. §§ 68.115 and 68.130. During the inspection, the EPA representative observed alleged violations of section 112(r) of the CAA, 42 U.S.C. § 7412(r),...

Read More

January 5, 2023

Respondent is an owner and operator of a petroleum refinery. Refining operations at the Facility are currently idled. EPA conducted an inspection of the Facility on September 20 – 26, 2022, to assess compliance with Section 112(r) of the CAA (the “Inspection”). During the Inspection, and in a letter dated October 13, 2022, EPA informed Respondent of observations made during the Inspection. EPA...

Read More

January 4, 2023

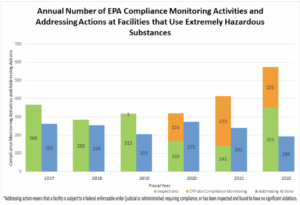

In FY 2022, the agency continued its efforts to reduce risks of accidental releases at industrial and chemical facilities, such as: Concluded three (3) judicial actions, 145 administrative penalty actions, and 18 administrative compliance orders In FY 2022, EPA renewed its presence in the field and increased its on-site inspections by more than 150% compared to FY 2021. EPA has addressed serious...

Read More