CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

January 4, 2023

As we have discussed at length, OSHA is in the process of updating the HAZCOM Standard (1910.1200) to reflect GHS Rev. 7. The most significant change in this adoption will be how Flammable Gases are categorized in 1910.1200 Appendix B, and this will also impact the PSM standard (1910.119) application. Here is OSHA’s official justification for these changes: … HomeRead More...

Read More

January 4, 2023

The Respondent operates plastics material and resin manufacturing processes at the Facility that produces polymers used in various applications and products, meeting the definition of “process “, as defined by 40 C.F.R. § 68.3. The Respondent produces, processes, handles, and stores 1,3-Butadiene, Chlorine, Propylene oxide, and Acrylonitrile at the Facility. On February 2, 2022, an incident...

Read More

January 4, 2023

OSHA’s VPP efforts in process safety has offered the following questions regarding the PSM activities in the process. Here are seven questions that will help you gauge your level of PSM expectations related to ammonia refrigeration:

…

HomeRead More »

Read More

January 4, 2023

Mr. Trevor Kletz is, without a doubt, my favorite author. In 2001 he published his book on Human Factors in process safety – “An engineer’s view of human error” (Third edition). It is a MUST-READ for those who practice process safety, significantly if you facilitate process hazard(s) analysis (PHA), including the Human Factors analysis. His book is quite telling,...

Read More

January 3, 2023

Admiral Rickover’s 7 Steps to Safety Success need to be adhered to today more than ever! They are simple and timeless, as he lived by them in the 1950’s and 60’s while building the U.S. Navy’s Nuclear Power program.

…

HomeRead More »

Read More

January 1, 2023

A safety management system should mirror the manufacturing process’s quality management system. The only difference is the “customer”… in the manufacturing process the customer is external – in the safety process, our employees are our customers.

Both management systems REQUIRE SAMPLING and ACCURATE process measurements.

Read More

December 31, 2022

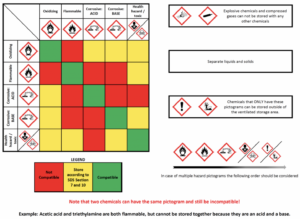

Safe storage, handling, and transfer of hazardous materials is key to reducing chemical accidents and dangerous mixtures of incompatible materials. Close storage of incompatible chemicals could create a risk of fire, explosion, or release of toxic gases and fumes. Storage locations should be according to the fire code, have proper fire protection, and are structurally appropriate. The Emergency Planning...

Read More

December 31, 2022

In OSHA’s fiscal year (October 2021 through September 2022), the agency conducted 151 Respiratory Protection inspections and issued 325 citations, with penalties totaling $1,388,505. 62311 / Nursing Care Facilities (Skilled Nursing Facilities) was #1 in Citations with 325 62311 / Nursing Care Facilities (Skilled Nursing Facilities) was #1 in Inspections with 151 62211 / General Medical...

Read More

December 31, 2022

Over the last several years, OSHA has asked, in the annual Supplement B questionnaire, specific questions designed to help share information about the site’s safety and health management systems (SHMS), but mainly about the critical areas of PSM programs and established procedures used to maintain, collect, and analyze PSM systems/process metrics. In 2016, OSHA developed a Fact Sheet, “The Use...

Read More

December 29, 2022

Background: CP rectifiers protect pipes against corrosion. Their use is mandated on liquid and gas pipelines by the Department of Transportation’s (DOT), 49 CFR § 195.573 (liquid pipelines) and § 192.465 (gas pipelines). While 29 CFR 1910.147 standard may control the hazards associated with the operation of CP rectifiers, it does not eliminate the other sources of electrical current employees...

Read More

December 29, 2022

Does § 1910.37(b)(7) permit the display of the ISO’s international emergency exit symbol as defined in ISO 7010 beside the mandatory EXIT text on an existing exit sign?

…

HomeRead More »

Read More

December 29, 2022

The Respondent owns an alkoxylation process at the Facility. Respondent manufactures a range of specialty surfactants for use predominantly in the oil and gas industry. The process of ethoxylation involves reacting ethylene oxide with various common chemicals , such as fatty alcohols and phenols, to produce a variety of products. The plant can also use propylene oxide instead of (or as well as) ethylene...

Read More