SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

July 13, 2021

The 2021 NBIC Draft Edition has been officially approved by the NBIC Committee. The list of major changes found below will appear in the 2021 NBIC. The four-part set:

Part 1- Installation (162 Pages)

Part 2- Inspection (402 Pages)

Part 3- Repairs and Alterations (312 Pages)

Part 4- Pressure Relief Devices (144 Pages)

will cost $325 or you may purchase each part separately for $115 to $150 each. ...

Read More

July 13, 2021

Much like The National Board did, ASME is now splitting out its relief systems into a new section. The NB created Part 4 – Pressure Relief Devices in 2017 and now ASME is following suit and has created Section XIII, Rules for Overpressure Protection (available 7/31/21). This new section in the 2021 edition of the BPVC will include:

…

HomeRead More »

Read More

July 7, 2021

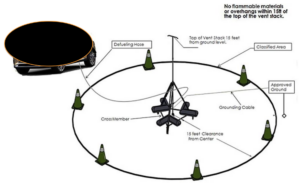

For 20 years now, when teaching any of my process safety courses I make the student repeat this three times: UPWARDS and UNOBSTRUCTED, UPWARDS and UNOBSTRUCTED, UPWARDS and UNOBSTRUCTED. We do this when we get to the Relief System design basis. The vents to the atmosphere almost will always be required to be UPWARDS and UNOBSTRUCTED based on just about any RAGAGEP for hazardous materials. ...

Read More

July 7, 2021

A few years ago I was asked to participate in a hazard assessment for a manufacturer who wanted to review the procedure for hydrogen-powered vehicles to be freed of hydrogen gas. I got the feeling very early into this hazard assessment that those in the room knew about an event of some type, but wanted me to walk them through the venting process so they could quietly find their error(s).

I conducted...

Read More

July 7, 2021

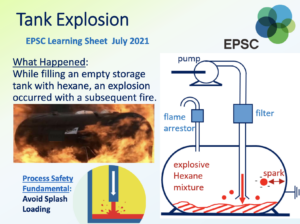

This is an EXCELLENT 1-page Alert on the hazards of “Splash filling” non-conductive flammable liquids. SPEED MATTERS, as does process design!

To read more on handling non-conductive flammable liquids CLICK HERE

Read More

July 6, 2021

On January 17, 2020, EPA performed an inspection of the Facility pursuant to Section 112(r) of the CAA, Sections 304-312 of EPCRA, and Section 103 of the Comprehensive Environmental Response, Compensation, and Liability Act. Based upon the information gathered during this inspection and subsequent investigation, EPA asserts that Respondent violated certain provisions of the CAA and EPCRA. At all times...

Read More

July 2, 2021

So in my previous post, we covered the SIZE of the EXIT signs and in this post, I want to cover the “illumination” requirements of these EXIT signs. Simply stated, OSHA and the IBC require the face of the sign to be illuminated to at least 5-foot candles or 54 Lux at ALL TIMES. Which is NOT a lot of light. Of course, when the area has its normal lights on, meeting this illumination...

Read More

July 2, 2021

Earlier this year we were asked to assist in a site assessment after a tragic accident. During this assessment, it was hard not to notice all of the brand new exit signs the facility had put up (i.e. stuck up as they were stickers). These signs were super clean as compared to the rest of the facility so they really stood out during our “side-walk tour” of the facility and the...

Read More

July 2, 2021

Be careful, experience shows that most who read this will find it offensive…

Meet “Ed”, he is just a maintenance worker I meet in 1994. My first impressions of Ed were he was safe (i.e. always followed the safe work practices, always had on his PPE properly, etc.) based on my personal observations. One day I mentioned Ed and was quickly shut down and mocked for even mentioning...

Read More

July 1, 2021

Respondent owns and operates a chemical manufacturing facility that has a chlorine (Cl2) process at the stationary source in excess of the applicable threshold quantity. The chlorine-covered process is subject to the “Program 3” requirements of the Risk Management Plan (RMP) regulations and must, among other things, to comply with the Program 3 Prevention Program of 40 C.F.R. Part 68, Subpart...

Read More

July 1, 2021

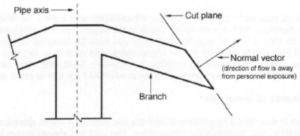

I love the Line Break and Equipment Opening (LEO) SWP because it is one of the most hazardous tasks a worker will perform within a covered process AND the fact that there is no OSHA standard dictating how a business manages these risks. This lack of “OSHA Control” spoon-feeding us safety requirements causes most management groups to be lost in the risk and allows us (safety engineers/professionals)...

Read More

June 30, 2021

This case involves a citation regarding the “grandfather training clause” found in both OSHA’s PSM and EPA’s RMP. I have never seen it cited before, but I take my hat off to the EPA inspector for peeling that onion!

Basically, this food facility had two (2) employees who had been hired in January and September 1996. The facility was unable to produce certification...

Read More