SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

June 1, 2021

I have written about this topic numerous times, and each time it causes controversy among the SAFTENG members. Some members are adamant that we should NEVER allow any “intervening valve(s)” in our pressure relief systems; others have seen it done many times. ASME VIII does indeed allow “intervening valves” before and/or after a Pressure Relieving Device (PRD), and...

Read More

May 30, 2021

At 8:30 a.m. on June 22, 2020, Employees #1, 25, and #2, 47, employed by a piping company, were working on the roof of a three-story food processing company. They were adding new pipe to two (2) new, already installed, 14-inch diameter chilled water lines. The chilled water lines had been pressure-tested with nitrogen.

…

HomeRead More »

Read More

May 29, 2021

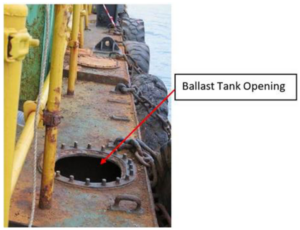

On May 19, 2021, a supervisor entered a dredging vessel’s ballast tank for an inspection. The supervisor entered the tank without any appropriate Personal Protective Equipment (PPE) and did not check if the confined space was safe. Shortly after entering, he collapsed and passed out. After some time, another worker entered the tank in an attempt to rescue the supervisor, but also passed out upon entry....

Read More

May 29, 2021

A petrochemical plant has been fined after ethylene, a flammable gas was released from a cracked pipe at the Ethylene Plant. On May 2, 2017, approximately 17 tons of ethylene were released from the pipe. This leak precipitated the formation of a flammable gas cloud of around 2,295,453 cubic ft. The gas cloud was seen to move through a congested area of the plant reaching ground level. An investigation...

Read More

May 29, 2021

The report said an abnormal flow of electricity occurred as a result of “improperly grounded equipment” in the roof area of the tank, a static discharge or ignition charge in the tank was the “most probable cause of ignition” in the October 15, 2019 incident. The tank’s roof was blown off & landed on a nearby tank, which in turn exploded within...

Read More

May 29, 2021

Many of us manage a Respiratory Protection Program for all types of respirators and many types of hazards. What many programs lack is the annual evaluation of the program and its execution. The written program should contain information on how and who will perform this evaluation and although the standard does not state this evaluation be done annually, I would strongly suggest this frequency. ...

Read More

May 27, 2021

This past January 2021, The Chlorine Institute issued Edition 7 of their Pamphlet 65 – Personal Protective Equipment for Chlor-Alkali Chemicals (which is available for FREE). This is a MUST have document for those who have exposures to:

CHLORINE

SODIUM AND POTASSIUM HYDROXIDE (10 – 50 WT %)

SODIUM HYPOCHLORITE (3 – 20 WT %)

HYDROCHLORIC ACID (7 – 37 WT %)

SULFURIC ACID (38...

Read More

May 24, 2021

A plastics plant experienced a release of approximately 15,825 pounds of styrene vapor from a railcar on 9/1/2020. The railcar had been on the property since May 2020 (4 months). The styrene began its reaction inside the railcar once the inhibitor had been consumed, leading to the release and evacuations ensued for those located around the facility.

The state’s EPA issued a notice...

Read More

May 21, 2021

Respondent is a plastics material and resin manufacturing plant that produces polyvinyl alcohol from the vinyl acetate process. EPA conducted an inspection of the Facility on May 15 through 17, 20 I8, to determine Respondent’s compliance with 40 C.F.R. Part 68 (the Inspection).

…

HomeRead More »

Read More

May 13, 2021

In the latest craze with “lean manufacturing”, a lot of businesses are rearranging their production lines and in a lot of cases, safety was not a serious consideration. We see a lot of emergency egress issues, serious electrical power constraints leading to improper power cord usage, fire extinguisher types and placement issues, etc. But the one item that seems to not find its...

Read More

May 13, 2021

Scenario: You have a hazardous material that has a really low PEL and STEL and the process where it is going to be used is an “open process”. Management ask you to perform a hazard assessment and it is determined that the room where this material will be used will need ventilation to ensure exposures are properly managed. Where do you turn to find your ventilation/exhaust...

Read More

May 13, 2021

I have always wanted to do this for my own use and over the pandemic, I took the time to compile a breakdown of some of the hazardous materials my clients have into Highly Toxic and Toxic so as to be clear which design requirements apply to which hazardous materials (HAZMATs). For some of these HAZMATs, I knew which level they belonged to as I work with them monthly, but there were a few surprises. ...

Read More