Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

June 4, 2025

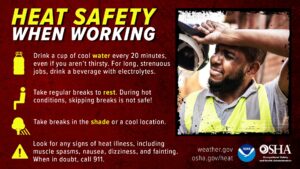

It’s hard to believe that 2025 is already at its halfway mark. Temperatures are rising and humidity is creeping in for many workplaces, so it’s time to start measuring, monitoring, and responding to high-heat working conditions. Don’t ignore this hazard simply because OSHA has not yet promulgated a standard. Do it for your PEOPLE, not for OSHA.

Read More

June 4, 2025

Fill out this form to ask a workplace safety and health or retaliation question or to request a letter of interpretation. Responses to questions will be sent within ten business days, but interpretation requests take longer. All responses are for informational purposes only, and do not constitute an official communication of the U.S. Department of Labor or OSHA. For an official response,...

Read More

May 31, 2025

If you don’t know me and are confused as to what makes me tick as a safety pro… it’s data! And not just any data – VERFIED AND VALIDATED DATA! And this leads me to “on-line reviews”. I hear a lot of people refer to these on-line reviews about vacation rentals, restaurants, and products. They are serious about convincing themselves “it must be ok, just look at all these 5 star reviews”. I’m sorry,...

Read More

May 31, 2025

This paper concerns refrigerant gases classified as Division 2.1 flammable gases under the Australian Dangerous Goods Code (ADG Code) or classified as Flammable Gas Category 1 using the Globally Harmonized System (GHS). It covers general work health and safety/occupational health and safety (WHS/OHS) duties, however, readers should check their legislative responsibilities at the state/territory and...

Read More

May 31, 2025

On 6 December 2016, an operator at a liquefied petroleum gas (LPG) processing facility heard a loud noise coming from an area of the plant during start-up, following major maintenance on the process. The operator identified that high-pressure, flammable gas was being released to the atmosphere from a point beneath the insulation of process equipment. Once the incident was contained, the area was secured...

Read More

May 31, 2025

In April 2024, a regeneration gas heater ruptured at a gas processing plant due to an overheated electrically heated regeneration vessel. Regeneration gas heaters are commonly used in the regeneration of molecular sieve dehydrators with the recirculation of dried natural gas heated to 250 degrees Celsius throughout adehydrating purge cycle. The initiation of manual operating mode, together with an...

Read More

May 31, 2025

A worker was exposed to NH3 while working next to a live refrigeration unit. The worker was working from an elevating work platform (EWP) to install a partition wall in a large refrigerated space. The EWP was in close proximity to a chiller unit that was operating during the work. The EWP knocked a valve on the chiller unit, releasing high-pressure ammonia refrigerant. The worker was sprayed in the...

Read More

May 30, 2025

If the company leadership team, including the Board of Directors (BOD), cannot explicitly state what they want from the EHS team and what level of performance they wish to achieve, then we are being set up to fail. I am amazed at how a leadership team will claim a multi-million-dollar project was a “safety project” and how they are “investing in safety.” When none of them could...

Read More

May 30, 2025

Recently, I visited an old client after a long absence. As I pulled into the parking lot, I immediately noticed the upgrade to the freshly paved and striped parking lot. My last visit, years earlier, I ended up parking in a crater in a gravel lot that some smaller cars would not have been able to traverse (yes, it had potholes deep enough and large enough to swallow a compact car). And sadly, the facility...

Read More

May 30, 2025

A long-time friend (Bill Conlon, President at Pintail Power) and a remarkable engineer (not officially an SE- LOL) shared with me his first published article, from April 1975, in which he argued against relying on Administrative Controls and instead advocated for safety through design as the way to manage risks. Now, for a man who has several engineering patents, a PhD in Nuclear Engineering, and is...

Read More

May 30, 2025

Respondent owns and operates a prepared foods processing plant located within one mile of a residential area, an elementary school, a pond, a river, and many businesses. Respondent uses anhydrous ammonia in a refrigeration process,” as defined by 40 C.F.R. § 68.3, in a series of interconnected pipes and vessels at the Facility (the “Process”). In 2020, Respondent filed a Program 3 RMP for the Process...

Read More

May 30, 2025

Respondent operates a chemical manufacturing facility which has on-site for use, 25,299,678 pounds of anhydrous ammonia and 355,094 pounds of ammonia (concentration 20% or greater). Respondent has two RMProgram level 3 covered processes, that store or otherwise use anhydrous ammonia and ammonia (concentration 20% or greater) in amounts exceeding their applicable thresholds of 10,000 pounds and 20,000...

Read More