SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

February 24, 2019

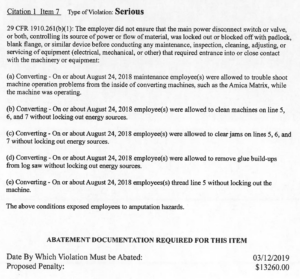

This week we saw OSHA issue $300K in citations to a MS papermill, of which LOTO was an area that was cited. One particular situation that caught my eye was the citation regarding “troubleshooting” behind a guard…. (see item (a) below)

…

HomeRead More »

Read More

February 23, 2019

This is one type of situation where (c)(5) could be a means to enter a PRCS and OSHA agreed and issued some (c)(5) citations.

At 8:15 p.m. on May 25, 2018, Employee #1 was power washing the outside of the semi-truck tanker trailer. The employee entered the tanker trailer to wash the inside and was not found for two hours. The fire department was called to rescue the employee. Atmospheric monitoring...

Read More

February 23, 2019

At 11:00 a.m. on June 1, 2018, an employee was transferring a chemical degreaser containing 1-5% caustic sodium hydroxide, from a 5-gallon jug into a small bottle. The chemical spilled onto the employee’s left hand and pants. The employee took off his pants, wiped his legs with wet cloths, and changed clothes. However, the employee refused to seek medical care, providing that he would shower...

Read More

February 23, 2019

At 2:30 p.m. on March 10, 2018, Employee #1 was using an aerial lift to gain access to an emergency access panel on a dust collection silo that was 25 feet above the ground. From the aerial lift, Employee #1 was using a two-inch water hose to spray water into the silo to remove the sawdust that had accumulated. He then exited the aerial lift and climbed through the emergency blow-out panel that opened...

Read More

February 23, 2019

This case is a perfect example of how OSHA will use the newer Construction Confined Space Standard in a general industry workplace based on the actual work being performed.

At 3:30 p.m. on May 3, 2017, Employee #1 was spray coating the inside of a 6 foot by 23-foot stainless steel tank, using Plasite 7133, a Category 2 flammable liquid (Flash point < 23°C (73.4°F) and initial boiling point...

Read More

February 23, 2019

On May 5, 2018, Employee #1 was retrieving a plastic liner bag from a chemical container that had fallen into Reactor CP-2; a confined space. The permitting process, including air monitoring and setting up of ventilation, had not been conducted. As Employee #1 descended a ladder to access the reactor, he passed out at the first rung and fell to the bottom of the reactor. A coworker, who witnessed Employee#1...

Read More

February 23, 2019

At 4:00 p.m. on January 5, 2018, Employee #1, employed by an industrial cleaning company, was working at a multiemployer project. He was working from an 8-foot stepladder, Werner Fiberglass 300-pound capacity P/N 100521-127 Model Number T6208 Mk 4. He was 2 feet above the ground and monitoring and adding water as necessary to evaporator pans to prevent freezing. The float system on the evaporator failed,...

Read More

February 21, 2019

Recently I came across a situation at a facility that is NOT all that uncommon and we need to spread the word. It involves using an electrical disconnect on an electrical panel door. As you will see in the STAGED video (NO one was at risk in the video) that I turned the disconnect off, placed my LO lock on the disconnect. Doing so, an authorized employee would expect to have EXCLUSIVE...

Read More

February 17, 2019

There may come a time that we need to pressure test one of our pressure vessels after a repair or alteration and our FIRST CHOICE of methods to use should be Hydrostatic as it is MUCH SAFER than pneumatic. However, in some cases, we may NOT be able to perform a hydrostatic test for a couple of common reasons:

the vessel is not capable of holding the weight of our hydrostatic test media, typically...

Read More

February 16, 2019

Some processes have a relief system that includes a rupture disk below the relief valve. This is done for several reasons, but the two most common reasons are:

The process is corrosive and can cause issues with the Relief Valve leading to failures and a shortened life span

The process contains a Category M fluid and any leakage, ever how minor can lead to serious hazards

But...

Read More

February 15, 2019

On August 27, 2016, about 8:26 a.m. EST, a railroad tank car sustained a 42-inch long crack in its tank shell shortly after being loaded with 178,400 pounds of liquefied compressed chlorine at a chlorine manufacturing plant in West Virginia. Over the next 2.5 hours, the entire 178,400-pound load of chlorine was released and formed a large vapor cloud that migrated south along the Ohio River valley....

Read More

February 15, 2019

One of the recent amendments of EPA’s RMP rule impacted our Incident Investigation procedures/practices and most likely any report forms we had been using for years and years. The RMP and PSM Incident Investigation elements used to be very similar and thus most of us used the same procedure/practices and forms when trying to comply with the two (2) elements. But now, since EPA had to implement...

Read More