April Membership Special

3-years for $100

Just buy a Single User Membership and your $100 gets you three (3) years of access instead of one (1) year

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

October 15, 2015

Moments before a blast ripped through a railcar on April 14, 2015, a check of the air quality inside indicated a serious risk of an explosion. Despite the warning, the company sent two employees, aged 41 and 45, into the railcar to work without monitoring the air continuously for explosive hazards as required, nor providing the employees with emergency retrieval equipment or properly fitted respirators. ...

Read More

October 14, 2015

This was an atmospheric storage tank containing diesel fuel that failed under fire conditions. I believe this to be merely a failure of an atmospheric storage tank under fire conditions and the sounds from the video make it appear that the vent was either obstructed or an undersized vent OR the venting we hear just before the FF with the camera gets knocked down is the seam(s) of the tanks ripping...

Read More

October 14, 2015

There are five key differences from the construction rule and several areas where OSHA has clarified existing requirements. The five new requirements include:

…

HomeRead More »

Read More

October 14, 2015

There’s a reason why both OSHA and EPA have requirements to CONTROL the entry of contractors into our covered process(s), their presence, and their exit from the process. It is so IMPORTANT, we find two (2) places in the standards that require this kind of CONTROL over contractors who wish to work ON, IN, or ADJACENT to our covered process… (f) Operating procedures…(4) The...

Read More

October 14, 2015

One of the most popular PSM requests I get is for an example of a “change to facilities that affect a covered process”. In this article, I hope to provide an actual example and how a “change to facilities” can affect an ammonia refrigeration facility. OSHA’s PSM standard states the following about managing changes… (l) Management of change. (1) The employer...

Read More

October 12, 2015

Over 12,500 exclusive unsafe acts/conditions and accident/injuries photos and over 1,300 ppt’s & doc’s from more than 2,797 contributors! 2015 Fatality Tracker Electrical 35 (2014 =55) (2013 = 32) (2012 = 68) Forklift/Aerial 46 (2014 = 60) (2013=62) (2012 = 52) Mining* 21 (2014 = 401) (2013=87*) (2012 = 92*) *ONLY developed nations and legal mines Explosions 134...

Read More

October 11, 2015

CLICK HERE for the pdf. Many thanks to the CALOSHA Pressure Vessel Unit for sharing.

Read More

October 11, 2015

This is an old steel 2216 psi cylinder! Today’s fiber wrapped cylinders are HIGHER PRESSURE and weigh less so the response would be more than seen in this video. SCBA Inspections and Hydro static Testing are KEY to ensuring a SAFE CYLINDER.

Read More

October 10, 2015

7/7/2020 UPDATE: Found the OSHA Case where an evaporator fan motor bracket failed, causing the fan to fall onto the coil(s) and cause a NH3 release 6/30/2020 UPDATE: See my video of an NH3 Condenser Tube/Coil failure (Hydraulic Expansion) on my YouTube Channel In 2012 I attempted to convince you that ammonia evaporative condensers are indeed Permit-Required Confined Spaces. I hope...

Read More

October 10, 2015

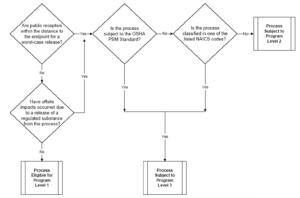

The recent change in OSHA’s PSM definition of a “retail facility” is having a large ripple effect all the way across EPA’s RMP rule. As I wrote about in “How does OSHA’s revised PSM “retail exemption” policy impact my RMP?” this change, thought by many as minor – thus the six-month compliance window for these facilities, is actually...

Read More

October 9, 2015

A grocer has settled with EPA for alleged chemical release reporting, risk management, and emergency planning violations at its warehouse facility in Seattle, Washington and will pay EPA a $110,200 penalty. The company will also complete a Supplemental Environmental Project which includes ammonia release detection improvements valued at over $180,000. The facility is a distribution center for grocery...

Read More