Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

October 19, 2024

An ammonia leak occurred inside the machinery room of a public athletic club with indoor ice facilities. The leak happened during the decommissioning work of an ammonia refrigeration condenser by a licensed refrigeration contractor, which resulted in the facility enacting its Ammonia Release Emergency Protocol. The incident was likely caused by the contractor not properly purging and vacuuming the...

Read More

October 19, 2024

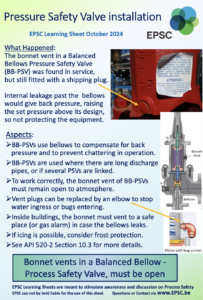

One of the top questions newcomers to process safety ask is, “Why do I have to have a written procedure to remove and install new relief valves?”From the EPSC Learning Sheet October 2024What Happened:The bonnet vent in a Balanced Bellows Pressure Safety Valve (BB-PSV) was found in service, but still fitted with a shipping plug. Internal leakage past the bellows would give back pressure,...

Read More

October 19, 2024

Respondent owns or operates the AMPI production facility that uses anhydrous ammonia in its refrigeration processes. From December 20, 2021, to May 17, 2022, EPA conducted an offsite compliance monitoring investigation of the Facility. During that investigation, the EPA representatives identified alleged violations of section 112(r)(1) of the CAA and section 312 of the EPCRA. EPA’S ALLEGED VIOLATIONS...

Read More

October 19, 2024

Respondent is the owner and operator of a facility that has more than 10,000 pounds of anhydrous ammonia and Hydrogen in processes. Information gathered during the EPA inspection revealed that Respondent uses anhydrous ammonia in the production of food ingredients and produces and stores hydrogen, and therefore, is engaged in a process at its facility. Allegations of Violation COUNT 1 The EPA inspection...

Read More

October 19, 2024

According to reports, thirteen (13) explosions, three (3) of which involved fatalities, occurred over the past ten (10) years, leading to the grounding of hundreds of refrigerated containers worldwide. The causes of the explosions were investigated and thought to have been caused by contaminated or incorrect refrigerant being added to the refrigeration system while it was in service in Vietnam. A shipper...

Read More

October 19, 2024

It has been 1-month since the tragic death of Greene County Fire Rescue Battalion Chief Chris Eddy in GA while working a semi-truck fire on the side of the roadway. We still have not received any formal information on this event, but there has been some erroneous reporting. Out of respect for Mr. Eddy, I promised to wait for official word on this accident’s cause and contributing factors....

Read More

October 19, 2024

It is a common question… why does OSHA define entry as… Entry means the action by which a person passes through an opening into a permit-required confined space. Entry includes ensuing work activities in that space and is considered to have occurred as soon as any part of the entrant’s body breaks the plane of an opening into the space. This work took place on a ship in a flammable...

Read More

October 19, 2024

A lot of folks recognize the need for mechanical exhaust ventilation in areas where there is a flammable and toxic exposure hazard. The general rule of thumb for this mechanical exhaust ventilation is 1 CFM per square foot of floor space with at least six air changes per hour. But there are two (2) other requirements that come into play that many systems do not have: Failure alarm Emergency...

Read More

October 19, 2024

1910.252(a)(3)(i) Used containers. No welding, cutting, or other hot work shall be performed on used drums, barrels, tanks or other containers until they have been cleaned so thoroughly as to make absolutely certain that there are no flammable materials present or any substances such as greases, tars, acids, or other materials which when subjected to heat, might produce flammable or toxic vapors. Any...

Read More

October 19, 2024

Way back in 2006, when Dennis retired after a nearly 40-year career with OSHA and came to work with me at SAFTENG, we always traveled together, and he TAUGHT me more about “safety management” during those trips than I had learned in the preceding 13 years in industrial safety. One of the items we discussed was, Is using a facility’s ability to comply with LOTO (1910.147) a fair measurement...

Read More

October 19, 2024

On April 6, 2024, at 9:30 a.m., a 72-year-old employee of a farm supply wholesaler was working on an anhydrous ammonia tank trailer on the south side of the shop. The employee was located near the tank’s valves and hose. While working on the tank, anhydrous ammonia was released. The employee died from asphyxiation from inhalation of the ammonia. Violations/Penalties Serious Willful Repeat Other...

Read More