CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 5, 2014

One of the methods EPA uses to determine RMP inspection priorities is based on their use of the Wharton School’s Hazard Index, which is defined as “the sum over all chemicals of log2 (maximum quantity of inventory on-site/threshold), or, alternatively, as the number of chemicals times log2 of the geometric mean of the maximum-to-threshold quantity ratio.” EPA has defined a “High...

Read More

April 4, 2014

UPDATED with the actual working EXCEL Spreadsheet so that members can sort the data as needed;as well I updated the #’s related to refrigeration below. I had messed up my first sort and was off by a couple. This week I raised a red flag regarding ammonia accidents after the UNLOADING FATALITY at a fertilizer facility, only to be told that it was the wrong “forum” (e.g....

Read More

April 4, 2014

In the past several years OSHA has renewed their efforts in trying to get their “Injury and Illness Prevention Plan” (I2P2) on the table for discussion/rule making. To many safety professionals this may be a “new movement”, but in reality this effort dates all the way back to 1995. Recently, OSHA has said they are hoping to have a formal rule making effort going by September 2014 and this...

Read More

April 4, 2014

Plastic Intermediate Bulk Containers (IBCs) are popular for shipping large quantities of liquids. But some of these containers also create a dangerous hazard. When UNLISTED composite IBCs (those that have NOT been inspected or certified to provide any fire endurance) containing combustible and flammable liquids are stored in large quantities they pose a high risk for pool fires. They melt quickly...

Read More

April 4, 2014

Canada’s consensus standard for Process Safety Management far surpasses OSHA and EPA’s versions. My favorite upgrade is how senior management has a few of its own sections in the standard. For example: Leadership commitment at all levels of an organization is key to achieving excellence in PSM and establishing a process safety culture. Management must be visible and must demonstrate...

Read More

April 3, 2014

NV-OSHA (state plan) have cited an oil refining company for three serious violations stemming from a December explosion that left one employee seriously burned. The action proposes the refinery pay up to $20,790 in fines. Final determination is still in the administrative process. According to the state, refinery workers were attempting to restore flow to an asphalt recycle line...

Read More

April 3, 2014

I have written often about how we should establish safe upper and lower limits for our covered process(s). (SAFTENG members can read Establishing Safe Upper and Lower Limits) One mistake we have discussed is related to safe upper pressures and its relationship to the MAWP of process vessels. We continue to see errors in such that a vessel with an MAWP of 300 psi, will have a Relief Device with...

Read More

April 1, 2014

There are some really good comments and there are some very political comments, which should be expected in this type of transfer of information. I did notice that NOT ONE of the commenters answered the 85 questions OSHA requested they answer to support their comments/positions. Here is what the RFI stated: OSHA is providing the following questions to collect data, information, and comments on the...

Read More

April 1, 2014

Yes, I am just a sick safety professional who needs help! You may have a point, but I just had to share this “human factors” learning experience from my wife and daughter. First, let me say that there are probably not many women smarter than my wife and 12-year-old daughter. Both women put me to shame when it comes to intelligence, and I state this as a fact and not as a _ss kissing...

Read More

April 1, 2014

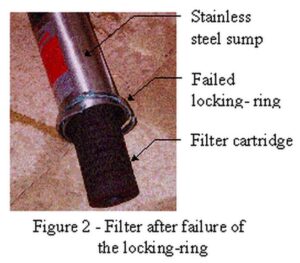

Purpose This Alert is issued to inform employers, self-employed persons, designers, manufacturers and suppliers of ammonia plant of a recent incident involving the failure of an oil filter. Background The failure of an oil filter on an ammonia compressor caused an ammonia leak and subsequent evacuation. One person was admitted to hospital but was released after several hours observation. The filter...

Read More

April 1, 2014

Here is the pdf http://www.usfa.fema.gov/downloads/pdf/coffee-break/cb_fp_2014_13.pdf

Read More