April Membership Special

3-years for $100

Just buy a Single User Membership and your $100 gets you three (3) years of access instead of one (1) year

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 29, 2024

The words “audits” and “inspections” often get used as if they are the same thing – THEY ARE NOT the same. I always like to say we inspect “things,” and we audit those inspections. Much like my previous post earlier this month, explaining the difference between “examinations” and “inspections” as used in ASME B31 series; the terms...

Read More

April 29, 2024

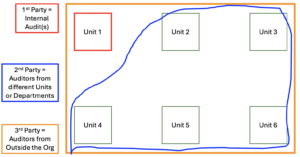

One of the more critical elements of an SMS is “auditing.” In the Plan-Do-Check-Act model, auditing falls within the “CHECK” function. I like to say it’s the element that keeps us honest and informed. And with that in mind, I break down my audits into three (3) layers: → 1st Party → 2nd Party → 3rd Party Each type of audit has its pros and cons, and the...

Read More

April 28, 2024

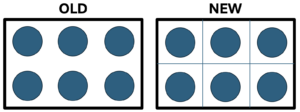

In the old days, the secondary containment around flammable liquid storage tanks could be a single system in which all the storage tanks sat. Today, that is NOT the case. Both NPFA 30 and IFC Chapter 57 require the secondary containment to be such that an LOPC from one tank can NOT impact the other tanks around it. They use the word “subdivided” to specify this. (emphasis by me) …...

Read More

April 28, 2024

If your team is focused on an event’s probability or likelihood, you’re NOT doing SIF! The Serious Injuries and Fatalities (SIF) model is intended to IDENTIFY events that have opportunities to cause life-altering injuries and death. And yes, most of these will (hopefully) have LOW frequencies/probabilities. So, to justify NOT responding to these LOW frequency – HIGH severity events...

Read More

April 28, 2024

The purpose of barrier[/controls/safeguards] management is to make the kind of implicit controls explicit: to be clear about exactly what controls are relied on to prevent incidents, to understand their characteristics, to have an understanding of how reliable they can be expected to be, and to know what needs to be done to ensure the controls are implemented and continue to function throughout...

Read More

April 26, 2024

Eight people, including five (5) contract workers and three (3) fire service personnel, were admitted to the hospital after they inhaled chlorine gas following a leakage at a water treatment plant.

…

HomeRead More »

Read More

April 25, 2024

Respondent operated a facility (the “Facility”) to manufacture chlorine, bleach, and hydrochloric acid. Respondent produced, used, or stored more than 2,500 pounds of chlorine at the Facility and was subject to the requirements of CAA § 112(r)(7). Respondent produced, used, or stored hydrogen at the Facility and was subject to the requirements of CAA § 112(r)(1). Respondent was subject to Program 3...

Read More

April 25, 2024

In terms of Fire and Building Codes, we have five (5) recognized areas associated with handling hazardous materials. We refer to these high-hazard areas/occupancies as “Group H”. High-hazard Group H occupancy includes, among others, the use of a building or structure, or a portion thereof, that involves the manufacturing, processing, generation or storage of materials that constitute...

Read More

April 24, 2024

During a recent design review, we encountered some questionable “normal breathing” designs. I have always used the simplest of tests to ensure the tank has ADEQUATE venting during filling and emptying. Although OSHA allows the designer to use API 2000 (1968) or “other accepted standards,” the simplest test is that the VENTING capability MUST be as large as the filling or withdrawal...

Read More

April 24, 2024

“We were doing some cleaning at the end of yesterday. I boiled some water in the HLT to pump through the heat exchanger. At the end of the day, there were 40-50 gal left in our 3bbl HLT. I turned off the heat and went home for the night. The next morning, I came into the brewery to find an imploded HLT. I had clamped the lid on to keep humidity down in the building, and the cooling air/water...

Read More

April 24, 2024

An ISO container, partly filled with Monoethylene Glycol (MEG), imploded on the back deck of a ship, spilling around two cubic meters (528 gallons) of MEG onto the deck and to sea and causing unrepairable damage to the tank itself. There were no injuries. The tank was a 26-cubic-meter tank containing ten cubic meters (6600 gallons) of MEG. The implosion happened due to a vacuum created inside the tank...

Read More

April 24, 2024

OSHA has again found a large food manufacturer with a history of hazardous workplace safety practices in violation of dozens of safety and health hazards. The producer of glass-pack, canned, frozen, refrigerated, freeze-dried, and snack food products under it’s brand, as well as other private labels, also operates eight other manufacturing plants, including five in Pennsylvania and one each in...

Read More