CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

January 15, 2013

Many THANKS to my NEWEST and RENEWING Corporate Partners in Safety… since 2011 since 2007 since 2012 since 2012 2013 Fatality Tracker Electrical 1 (2012 = 68) (2011 = 81) (2010 = 90) (2009 = 100) Forklift/Manlift 2 (2012 = 52) (2011 = 84) (2010 = 110) (2009 = 88) Mining* 8 (2012 = 92*) (2011 = 248) (2010 = 480) (2009 = 586) *no longer includes China accidents Explosions...

Read More

January 10, 2013

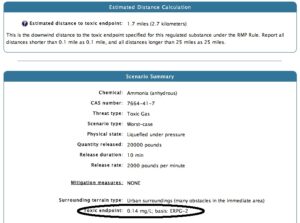

If you are an RMP site and have updated your RMP Submittal in the past couple of years you may have noticed a slight discrepancy in some of the data. In fact, the EPA guidance documents are also out-of-date with the ERPG-2 level for Ammonia still is being shown as 200 ppm. I am not sure about the many other Extremely Hazardous Substances (EHS), but I work with many Ammonia facilities, doing...

Read More

January 10, 2013

Although the agreement does NOT state the EHS involved, I am going to make a strong assumption that it is Chlorine. This inspection netted a whopping $980 in fines. Here are the elements allegedly violated:

…

HomeRead More »

Read More

January 10, 2013

Many THANKS to my NEWEST and RENEWING Corporate Partners in Safety… since 2011 since 2007 since 2012 since 2012 2013 Fatality Tracker Electrical 1 (2012 = 68) (2011 = 81) (2010 = 90) (2009 = 100) Forklift/Manlift 2 (2012 = 52) (2011 = 84) (2010 = 110) (2009 = 88) Mining* 8 (2012 = 92*) (2011 = 248) (2010 = 480) (2009 = 586) *no longer includes China accidents Explosions...

Read More

January 9, 2013

An amazing recollection and testimony from a survivor of what went on the night of the fatal Station nightclub fire! WARNING! This video may be upsetting to some, BUT it is one that every person NEEDS to watch. He lost his fiancée and several friends that horrific night. “The Station” a new documentary about the fire is scheduled to release in February of 2013...

Read More

January 9, 2013

Now this video was shot in China, but see how many unsafe acts you can count the operator of this front-end loader commits in this 8 minute video. Other than the obvious that he is not wearing his seatbelt and no back up alarm on the loader, how many can you spot? All I can say is just sit back and watch in utter amazement and the next time any one says “we do not need the Dept. of...

Read More

January 8, 2013

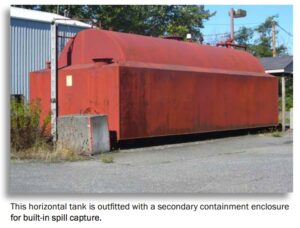

If you’re involved in process safety you know about mechanical integrity and what is mandated by OSHA’s PSM and EPA’s RMP in regards to MI. But many businesses are just scratching the surface with their mechanical integrity program(s). This article is meant to help those who are looking to take their MI program(s) to the next level. Using other government agency MI requirements...

Read More

January 7, 2013

Many THANKS to my NEWEST and RENEWING Corporate Partners in Safety… since 2011 since 2007 since 2012 since 2012 2013 Fatality Tracker Electrical 1 (2012 = 68) (2011 = 81) (2010 = 90) (2009 = 100) Forklift/Manlift 1 (2012 = 52) (2011 = 84) (2010 = 110) (2009 = 88) Mining* 0 (2012 = 92*) (2011 = 248) (2010 = 480) (2009 = 586) *no longer includes China accidents Explosions...

Read More