Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

January 6, 2012

Not a year goes by where I am teaching a HAZMAT or PSM course at a facility that has ammonia (NH3) where I am challenged on the fact that NH3 is explosive/flammable. I stress that it takes 160,000 ppm of the gas for it to burn, but it WILL BURN when it reaches this level – all that is needed is an ignition source! Of course, the only way anyone could be in 160,000 ppm of Ammonia gas...

Read More

January 6, 2012

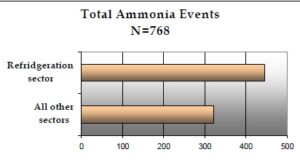

Some interesting data put together each year by the Wisconsin Department of Public Health Services. 2009 is the most recent update to their data. Here are the summaries: Since 1993, Wisconsin has had 768 uncontrolled ammonia releases, representing approximately 45 releases per year. 445 (58%) of Wisconsin’s ammonia releases involved refrigeration systems. A total...

Read More

January 5, 2012

Bryan, I am sure that you have seen some of the information on what OSHA is requiring Education Centers to do regarding monitoring OSHA Outreach Trainers. However, you may not have seen the details surrounding this program which I am attaching for your use. Attached is an internal OSHA document that went to all Education Centers that outlines the specifics of the monitoring program. In...

Read More

January 5, 2012

For all of you out there involved in behavior based safety, I have a TRICK QUESTION for you… Is it easier to convince people to AVOID an UNSAFE ACT or is it easier to get them to COMMIT a SAFE ACT? I ask this because I am trying to figure out a plan of attack for a particular unsafe act called “texting while driving”. As I sit here and think about what all is involved...

Read More

January 5, 2012

A little dark safety humor…

DRILL PRESS: A tall upright machine useful for suddenly snatching flat metal bar stock out of your hands so that it smacks you in the chest and flings your beer across the room, denting the freshly-painted project which you had carefully set in the corner where nothing could get to it.

…

HomeRead More »

Read More

January 4, 2012

MANY THANKS to my NEW & RENEWING “Partners in Safety”for their support! City of Boise, ID since 2007, Haynes since 2005, Air Products since 2009, Benjamin Moore Paints since 2011 2012 Fatality Tracker Electrical 1 (2011 = 81) (2010 = 90) (2009 = 100) Forklift/Manlift Mobile Equipment 1 (2011 = 84) (2010 = 110) (2009=88) Mining 0 (2011 = 248)...

Read More

January 3, 2012

We Believe

…That every man or women bears the unalterable responsibility for keeping out of harm’s way. This he or she owes to him or herself, their family, their fellows and his or her job.

…

HomeRead More »

Read More

January 2, 2012

Oily waste safety cans are an essential safety device where ever cloths and wiping rags are used with oils and solvents. Rags and cloths soaked with solvents, thinners, linseed oil, combustible adhesives and other flammable liquids present a serious fire risk if they are improperly discarded. These safety cans are specially designed to isolate it’s contents from fire sources and limiting...

Read More

December 31, 2011

Most businesses have established their safe upper and lower limits for the most obvious process parameters such as pressures, temperatures, and levels; but in a flammable liquid process involving non-conductive flammable liquids establishing a safe upper and lower limit for flow is an ABSOLUTE MUST. There is not a Recognized and Generally Accepted Good Engineering Practice (RAGAGEP) on flammable...

Read More

December 31, 2011

In the last two years we have seen a dramatic increase in the use of Anti-Static Wrist Bands in industrial settings. These wrist bands are designed and manufactured for “bench work” in highly controlled work spaces; not within an industrial setting.

…

HomeRead More »

Read More

December 30, 2011

Published by the Occupational Safety and Health Service, Department of Labour – Wellington, New Zealand

First published: 1982; Revised: 1990

…

HomeRead More »

Read More