CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

April 22, 2011

The Control of Hazardous Energy (lockout/tagout) standard regulates the servicing and/or maintenance of chemical process systems and associated piping, even though the energy sources (e.g., chemical and thermal energy) and control methods used in process hazards management are somewhat different from those encountered with machinery and mechanical equipment. Typically, the procedural steps required...

Read More

April 22, 2011

One of the most overlooked LOTO program requirements is the “Means to Enforce”.

OSHA regulations state the following about procedures to enforce the program…

…

HomeRead More »

Read More

April 22, 2011

Do you include your Fire Extinguisher company under your PSM/RMP Contractor Safety Program?

…

HomeRead More »

Read More

April 22, 2011

FIRE EXTINGUISHER FATALITY Youth killed while demonstrating safe use of fire extinguisher.

…

HomeRead More »

Read More

April 22, 2011

Many THANKS to my NEW & RENEWING Corporate Partners in Safety! since 2005 since 3/2011 since 2007 since 3/2011 2011 Fatality Tracker Electrical 11 (2010 = 90) (2009 = 100) Forklift/Manlift Mobile Equipment 31 (2010 = 110) (2009=88) Mining 65 (2010 = 480) (2009 = 586) Explosions 73 (2010 = 246) (2009 = 302) Cranes 14 (2010 = 50) (2009 = 82) Falls 36 (2010 = 139) (2009 = 172) (2008 = 250) Work...

Read More

April 22, 2011

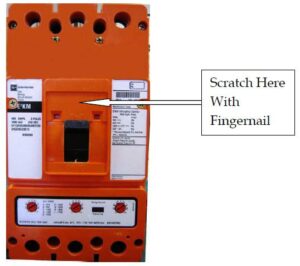

MSHA has been made aware of a hazardous condition that may exist in 600 volt and 1000 volt circuit breakers.

…

HomeRead More »

Read More

April 21, 2011

IncidentWorker was in the process of checking gauges when suddenly he felt a pulling motion on his right hip and back side. His coveralls had become entangled in an unguarded shaft and were being sheared off. Unable to escape or break free of the drawing motion the worker was able to reach the motor clutch and disengage the equipment, thus ending the ordeal. In the period of time (approximately 15-20...

Read More

April 21, 2011

What is management leadership in safety and health? Management demonstrates leadership by providing the resources, motivation, priorities, and accountability for ensuring the safety and health of its workforce. This leadership involves setting up systems to ensure continuous improvement and maintaining a health and safety focus while attending to production concerns. Enlightened managers understand...

Read More

April 21, 2011

1.) What is a Safety Contact? Safety Contacts are a conversation between a “manager” and an employee that is focused exclusively on safety! 2) Who is considered a Manager? A “manager” is considered to be all levels of management (usually defined by “exempt” status), but also includes the Leadership Team such as Engineers, Shift leads/ Supervisors, and other’s designated by the Business Manager or Safety...

Read More

April 21, 2011

Measurement is a key step in any safety management process and forms the basis for continuous improvement.

…

HomeRead More »

Read More

April 21, 2011

Below are examples of “measurable” and “auditable” safety activities that have proven to be effective when properly implemented, managed and measured. A) Job Safety Analysis – Each operation is required to perform _____(#) JSA’s a ________ (shift, day, week, month, quarter, etc.). These JSAs are required to be signed off by the Department Manager and filed for retention. ...

Read More

April 20, 2011

Over the years, I have had opportunities to work with some of the best HAZMAT Teams in North and South America on some really large scale incidents and through these experiences I have learned more than I could ever teach. But one thing that causes so many teams so many problems is their on-scene medical monitoring. Here are some very easy and cheap methods to help rectify these potential...

Read More