CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

March 21, 2011

No hunman and no organization is perfect! Although we should strive for perfection in all aspects of business (Production, Quality, Cost Control, and EHS), we often mis-step or possible loose our way altogether. But how bad do things have to get before it is a REAL PROBLEM?

…

HomeRead More »

Read More

March 21, 2011

Many THANKS to my NEW {amp}amp; RENEWING

Corporate Partners in Safety!

since 2007

since 2011

since 2009

since 2/11

2011 Fatality Tracker

Electrical

5

(2010 = 90)

(2009 = 100)

Forklift/Manlift

Mobile Equipment{amp}nbsp;

27

(2010 = 110)

(2009=88)

Mining

43

(2010 = 480)...

Read More

March 20, 2011

I continue to see facilities struggle with the emergency shutdown SOP requirements and how it is all suppose to flow and fit into the daily operations. In this post I will try and lay out a flow to help make sense of these PSM/RMP requirements. I am hopeful you can learn from my mistakes, as I have learned this the hard way from many OSHA inspections and accident investigations.

…...

Read More

March 20, 2011

We do not see these types of failures often, but when we do it can almost always be traced back to human error. Back in 2008, a tube and shell heat exchanger catastrophically failed when workers accidentally closed two different valves at two different times between the vessel and its relief valve. On June 10, 2008, operators closed an isolation valve between the heat exchanger shell (ammonia...

Read More

March 20, 2011

Does the title make you scratch your head? I usually get some strange looks when working with a client who is trying to understand what the PSM compliance cycle looks like. To start with, let’s look at what OSHA/EPA requires in our operating procedures:

1910.119(f)(1)(ii) Operating limits

1910.119(f)(1)(ii)(A) Consequences of deviation

1910.119(f)(1)(ii)(B) Steps required to correct or avoid...

Read More

March 20, 2011

If your PSM/RMP covered process contains a flammable liquid, 1910.106 has provided us with some regulatory facility siting requirements that we can quickly inspect to ensure we meet the minimum compliance distances. If you have liquefied petroleum gases within your facility, 1910.110 provides some basic siting requirements that should be met to have an argument that the propane will not impact your...

Read More

March 20, 2011

Many chemical processes that are covered under OSHA’s PSM and EPA RMP rules utilize one of the most popular forms of passive mitigation ever known…Diking. However, on the other hand, many of the facilities have not included their dikes in their Process Safety Information (PSI) or their Mechanical Integrity Programs (MIP).

…

HomeRead More »

Read More

March 20, 2011

I had an interesting dissertation given to me on how to calculate “frequency” when analyzing a PHA scenario during a recent PHA. Although it sounded logical, it was completely off base and thus would have shown the facility at very low risk for all their scenarios. This is something we see from time to time so I thought I would provide my two cents on the matter.

1) PHA participants should...

Read More

March 20, 2011

Since the great recession of 2008 -2010 we have seen an increase in the used equipment market. This is due to so many businesses going under and auctioning off their equipment and the remaining businesses needing to find ways to save $.

…

HomeRead More »

Read More

March 20, 2011

So, who has to do Confined Space Evaluations, and when must this evaluation be done?

The short answers are ALL General Industry (1910) employers and at the time the standard was promulgated and before each entry. Let me explain…

…

HomeRead More »

Read More

March 20, 2011

One of the most asked-about standards is OSHA’s Permit-Required Confined Space (PRCS) standard. The standard can be difficult to decipher, so this post attempts to break down an employer’s entry options. We should view the standard as offering three (3) entry options. Each option has its own set of rules and pros and cons.

Once a facility has completed its Confined Space/Permit Required...

Read More

March 20, 2011

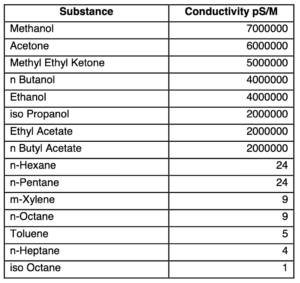

Like many safety professionals, I learned there is a HUGE difference in flammable liquids the HARD WAY. Having a strong background in fire/HAZMAT, even as an IFSTA instructor 20 years ago; I thought flammable liquids were all about flash points and LEL. To an emergency responder, that may work, but as a safety engineer responsible for a PSM/RMP-covered process containing non-conductive...

Read More