CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

March 10, 2007

Temporary Emergency Exposure Limits (TEELs) are guidelines designed to predict the response of members of the general public to different concentrations of a chemical during an emergency response incident. Note: TEEL values are NO longer included specifically in ALOHA, see PACs. TEELs estimate the concentrations at which most people will begin to experience health effects...

Read More

March 10, 2007

Emergency response personnel may have never heard the acronym AEGL, but that doesn’t mean it does not play a major role in the decision making process at almost all emergency responses to hazardous materials. AEGL’s and ERPG’s are the most widely used exposure guidelines in emergency responses to hazardous materials. In fact, did you know the DOT Emergency Response Guidebook...

Read More

March 10, 2007

The EPA’s Risk Management Plan (RMP) rule was the first time many EHS professionals had ever heard of Emergency Response Planning Guidelines (ERPGs). That was 1999, and still today 2007 there are many EHS professionals outside the PSM/RMP arena who still have not heard of ERPG’s. This article is an attempt to explain what they are and how they are used in emergency response...

Read More

December 20, 2006

Source Corrosion Rate or Degree of Corrosion Remaining Life or Fitness for Service Application API 570 Long-term (between last and initial inspections): (use corrosion rate resulting in shortest remaining life) Piping Short-term (between last and previous inspections): Piping and Vessels NBIC – 23 a) calculated from data collected by owner or user on vessels in the same...

Read More

December 20, 2006

Comparison of Piping Inspection Requirements in Refrigeration Industry Code Component Description Inspection Remediation Inspection Frequency IIAR 109 (1997) Uninsulated Pipe (4.7.4) Examine for corrosion Clean pipe down to bare metal and paint with rust preventative paint. “Badly corroded pipe should be replaced.” (4.7.4) – Annual ammonia safety check (5.2) – Thorough...

Read More

December 20, 2006

Comparison of Pressure Vessel Inspection Requirements in the Refrigeration Industry Code Type of Inspection Component Description Inspection Remediation Inspection Frequency IIAR 109 (1997) All pressure vessels If signs of more than mild corrosion should inspect further by a professional engineer or ASME inspector (4.3.5) None listed – Annual ammonia safety check (5.2)...

Read More

September 21, 2006

The following are all the “exemptions” permitted in EPA’s Risk Management Plan rule (40 CFR PART 68—Chemical Accident Prevention Provisions)

…

HomeRead More »

Read More

July 30, 2006

Below is OSHA’s official position on the need for hydrostatic relief valves in an Ammonia Refrigeration process. This is a bold move on OSHA’s part as the Ammonia Refrigeration industry and their trade groups have consistently stated that a “trained operator” is better than a hydrostatic RV.

(emphasis added by me)

…

HomeRead More »

Read More

April 10, 2006

I recently worked with a client on their emergency response efforts, and we continue to find businesses that do not understand the different requirements of qualifying a worker to use a respirator under CONTROLLED workplace exposures vs. UNCONTROLLED emergency response exposures. So, I wanted to write this article to make it as straightforward as possible… Employee A is hired into a job...

Read More

March 21, 2006

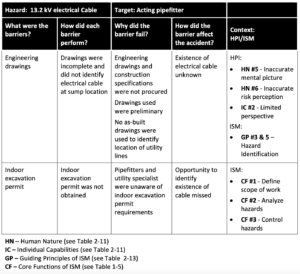

When analyzing barriers, investigators should first consider how the hazard and target could come together and what was in place or was required to keep them apart. Obvious physical barriers are those placed directly on the hazard (e.g., a guard on a grinding wheel); those placed between a hazard and target (e.g., a railing on a second-story platform); or those located on the target (e.g., a welding...

Read More

March 1, 2006

One of my favorite examples of Human Factors Engineering is the Center High-Mounted stop Lamps. We have all seen them on every personal vehicle manufactured today. They are now a safety requirement. But it was not always that way. So, what is a CHMSL? CHMSL are red stop lamps mounted on the center line of the rear of a vehicle, generally higher than the stop lamps on the...

Read More

February 16, 2006

Retail facilities are exempted from PSM requirements. At first glance, it appears this is a pretty broad exemption, as the standard just states. This section does not apply to:1910.119(a)(2)(i) Retail facilities; But as I wrote about last month, not all retail facilities selling a PSM Highly Hazardous Chemical (HHC) in the USA are exempt. In 2010, the state of Oregon began covering retail businesses...

Read More