Keep in mind the following was published in 1997 in Managing the risks of organizational accidents by James Reason. And he was not the first to say it, but he may have been the best at explaining it! Many organizations could make substantial improvements in their safety performance if they would just start measuring the “safety process” that is intended to reduce the injury rates rather than simply measuring and rewarding those rates. We hear a lot about “Zero Harm” and “Goal Zero” these days – it was recognized as a flawed approach 25 years ago, and it is still a flawed approach today. Having aspirations of zero harm is what most safety pros want; but aspirations are not the same as measurable goals.

Here is how Reason said in 1997…

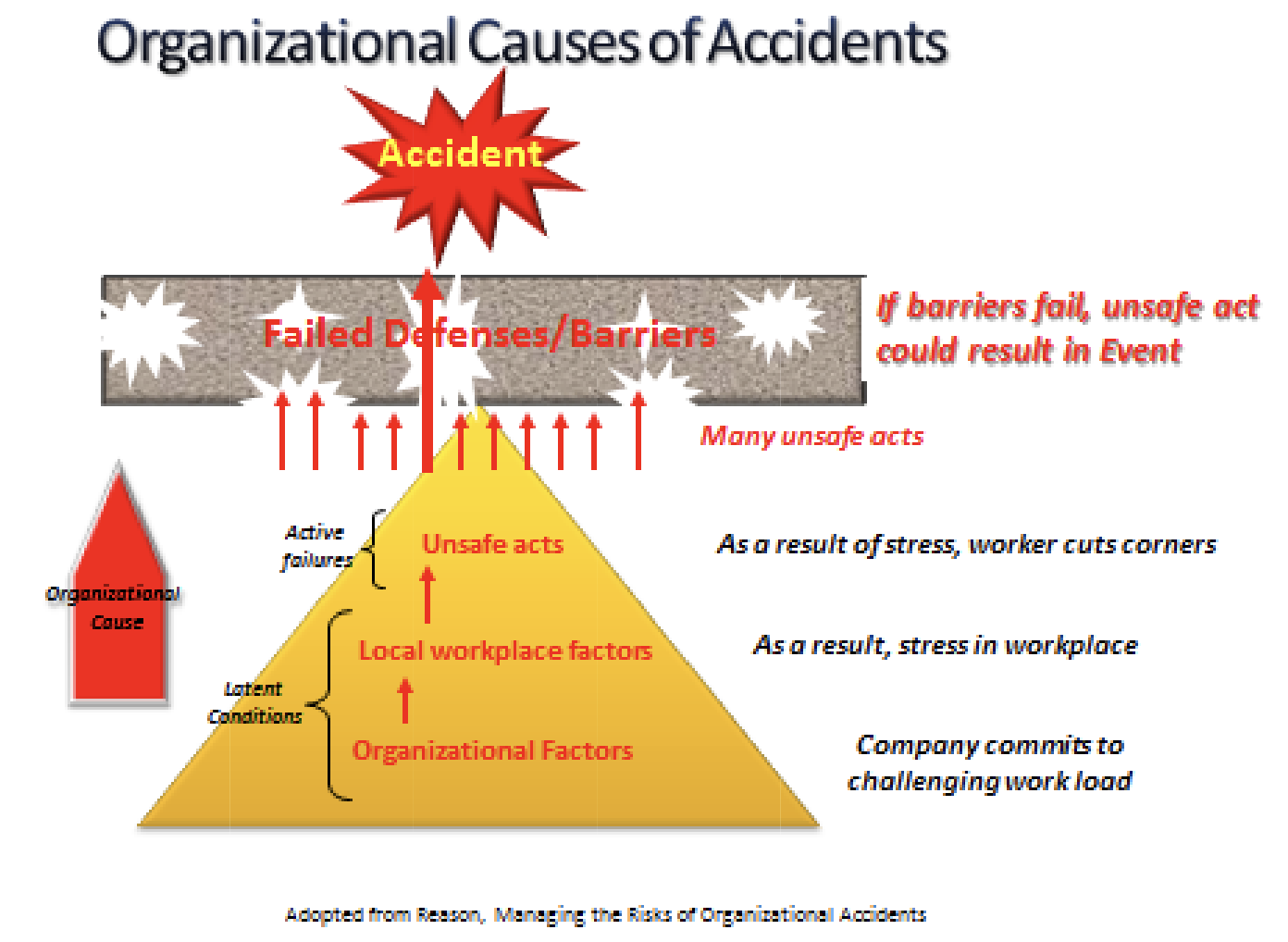

The key to navigating the safety space lies in appreciating what is manageable and what is not. Many organizations treat safety management as a negative production process. They set reduced negative outcome targets for the coming accounting period (e.g., “Next year, we’ll reduce our lost-time accidents by half”). But accidents, by their nature, are not directly controllable. So much of their causal variance lies outside the organization’s sphere of influence. The organization can only defend against hazards, it cannot remove or avoid them and still stay in business. Similarly, an organization can only strive to minimize unsafe acts, it cannot eliminate them altogether.

Effective safety management is more like a long-term fitness program than negative production.