I can remember “surviving” through safety stand-downs in my career and I can assure you, they were not coffee and donut parties! The stand-downs back then were TRUE stand-downs where the company halted the tasks/operations that were involved in the accident until the investigation was complete, the root cause analysis was complete, AND the corrective action plans were complete. These were very long days and nights, as in some cases the entire facility may be down costing millions of $’s each hour. On several occasions, we had processes/tasks across the globe shut down until such time we were confident we could SAFELY manage the risks associated with the operation/task.

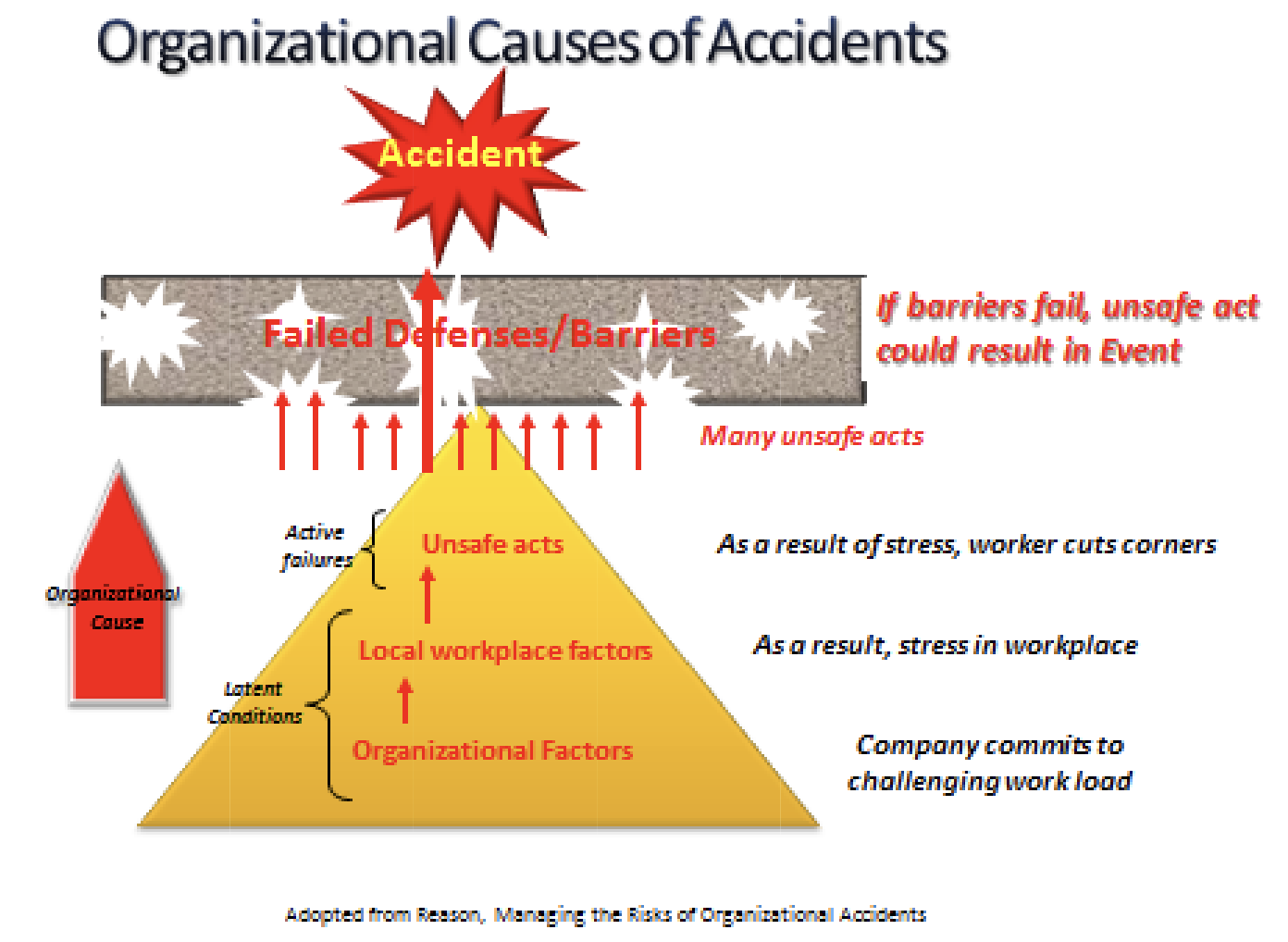

Tremendous resources were dedicated to ensuring no rock was left unturned and that we had a high degree of certainty that we identified the problem(s) and took appropriate actions ACROSS the ENTIRE business where these risks were present. These stand-downs were rooted in RISK MANAGEMENT principles using our causal analysis tools to identify both ACTIVE and LATENT organizational failures that led to the incident. And mind you, I experienced a couple of stand-downs as a result of near misses!