One of the top questions I get from “cold callers” or those who have joined SAFTENG and have digested my 400+ articles on Safety Management Systems and all their elements is:

So, what does an SMS do for me and my facility?

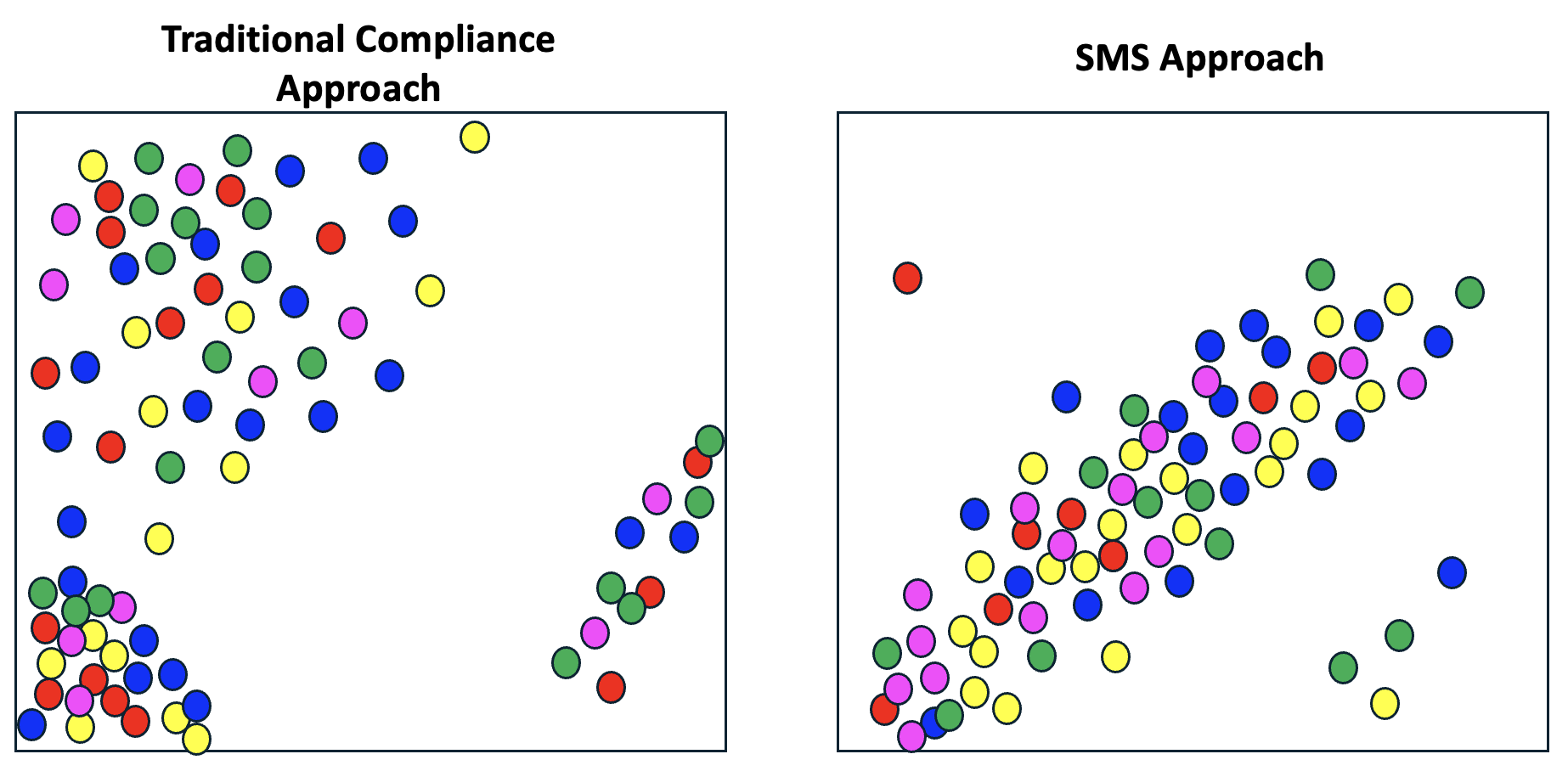

The best way to explain this is by an old scatter chart I had done in 1995 by a consulting firm we hired to help us achieve OSHA’s VPP STAR level of safety. This and OSHA’s PSM standard were my first exposure to a formal and structured SMS approach to managing safety. When the first chart was done, we were in the “compliance stage,” where we had the traditional “safety programs” that were “controlled documents,” and each control room had its “safety manual,” etc. Our programs were solid but individual programs that could stand independently but were not part of a more extensive “risk control” system. There were no metrics on the critical parts of the program(s) and no audit/validation/verification process that each program was functioning as intended and providing the level of safety we assumed it was providing.

Management was a bit concerned when the consultants explained that all of these new activities needed to be taking place; however, we already had a lot of “safety activities” going on. They were not sure how we would be able to manage all these additional activities. So the consultants, along with our Statistical Process Control (SPC) Group (before Six Sigma days), worked with the consultants to plot all of our “safety activities.” As you can see, we had a lot of safety activities. But were we getting our money’s worth?

Culturally speaking, we rocked it! We scored high on trust and credibility on all corporate climate surveys regarding safety matters. We probably had 80-85% of the hourly workforce participating in safety activities daily. However, we had plateaued in our injury reduction performance, and this was a cause of concern for our plant management and corporate management. It turned out “culture” can only take you so far in safety; at some point, we need to live within an SMS that builds on four (4) pillars of the safety/risk management: