Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

March 31, 2025

It is true that not all flanges and threaded joints have to be visually examined. However, this exemption is seriously limited.

(4) a sufficient number of threaded, bolted, and other mechanical joints selected at random to satisfy the examiner that they conform to the applicable requirements of para. 335.

Here is the qualifier…

…

HomeRead More »

Read More

March 31, 2025

A look back at OSHA’s 15 largest citations from 2015-2024. These figures are based on the INITIAL citations and NOT on the settled amounts. I have added the safety matter that drove the bulk of the citations. Just a tip… LOTO is by far #1 by a long shot (>50% of the cases). I’m not sure if we should cry or celebrate, but at least OSHA shows signs of getting serious with LOTO violations....

Read More

March 31, 2025

Maybe I’m just old school, but I have seen a strong focus on the safety fundamentals make tremendous progress in both performance and culture. Once we have milked the fundamentals for all they have to offer, then (maybe) our management system and culture will have matured to a point where we could manage a nice shiny cherry on top to drive that “continuous improvement” element to the next level. But...

Read More

March 31, 2025

A Delaware corporation with a manufacturing facility in Ohio pleaded guilty in federal court in the Southern District of Ohio to a charge of willfully violating an Occupational Safety and Health Administration (OSHA) rule. The criminal charge is related to an incident where an employee was killed when a pneumatic door closed on his head. The company operates several facilities in the United States,...

Read More

March 31, 2025

This case is a classic example of how Latent Organizational Failures INFLUENCE the decision-making of workers (and middle managers). At the end of this press release, the DOJ admits that “Company management had informed some of its employees that if operations came to a halt, the company would suffer serious financial harm, potentially including dissolution.” Also, the DOJ pointed out that...

Read More

March 31, 2025

Inspired by Stefan Kühl’s metaphor, the Safety Theater is a stage where people in an organization play their parts. From left to right:(1) A worker in full PPE flashes a big smile for the audit,(2) A corporate safety manager holds up a script labeled “Zero Harm”,(3) Backstage, a couple of managers whisper warnings about the financial bottom line,(4) Meanwhile, someone diligently sweeps...

Read More

March 30, 2025

I know I made these mistakes in my early years. In the early 1990’s “Behavior Based Safety” was all the rage, and it had me “hook, line, and sinker.” Sometimes, I wish I was still in contact with some operators/maintenance tech who got the raw end of our (mostly mine) investigations and causal analysis so I could apologize for my mistakes. It was not until I attended my...

Read More

March 30, 2025

A total of seven people were taken to the hospital after a chlorine gas leak was reported. The cause of the leak was a truck driver who delivered a chemical to a Water Plant and “unintentionally mixed two chemical compounds in a holding tank.” This then released the chlorine gas “from the tank vent.” The chemical reaction released chlorine gas from the tank vent, which drifted with the south wind into...

Read More

March 30, 2025

Interesting facts about this event: Safe Work/Line Break Permitting Energy Isolation Verification Emergency Escape Respirators Hydrogen Sulfide Detection (Personal and Area) Contractors On October 10, 2024, at 4:23 p.m., approximately 27,000 pounds of hydrogen sulfide gas were released during maintenance at the Refinery in Deer Park, Texas. The release fatally injured two (2) contract workers. Background...

Read More

March 29, 2025

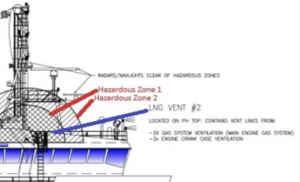

This United States Coast Guard alert supports my expectation that we must demarcate our HAZLOCs. I usually get pushback as the code does not explicitly require the boundaries of our HAZLOCs to be marked in any way. But in reality, if we want workers to respect the hazards of working inside a HAZLOC, then we need to help them know when they have entered these areas. This alert from the U.S. Coast Guard...

Read More

March 29, 2025

A recent marine casualty, resulting in a fire and severe injuries to two crewmembers, highlights the risks associated with:

Liquified Natural Gas (LNG),

Performing hot work in hazardous zones, and

the necessity of maintaining a robust lockout/tagout program

…

HomeRead More »

Read More