SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

February 14, 2020

The corrections concern the following regulations and standards:

…

HomeRead More »

Read More

February 14, 2020

In November 2019 a manager, 32, of a restaurant, a national chain, was overcome by chlorine gas and died. The investigation established that a worker at the restaurant spilled a “cleaner” on the floor during the day. Then later that night, a different employee started to clean the floor with a “floor cleaner”. The mixture of the previously spilled “cleaner”...

Read More

February 14, 2020

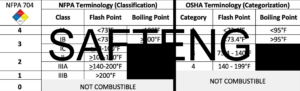

A client has allowed me to share work I did several years ago when OSHA’s GHS threw a wrench into the flammable liquids world! There was so much confusion between Class and Category of flammable liquids, and during an engineering review, it was discovered that the engineering group had made a conversion error when going from OSHA’s Categories back to Classes in order to meet local...

Read More

February 14, 2020

When most ordinary people hear the term “Hazardous Location” many conjure images of a dangerous location associated with typical hazards; however, when a safety engineer or engineer from the process industries hear the phrase we immediately elvate our antenna and sit up and pay close attention to what is being said. But for those outside of chemical processing indutries, most have...

Read More

February 13, 2020

In 2014, the Occupational Safety and Health Review Commission (OSHRC) issued a judgment on an OSHA case, and in the case, they made it clear that “magnitude” matters in lockout/tagout (LOTO). But for some reason, this piece of data is absent from many machine-specific LOTO procedures and OSHA always takes issue with this oversight. So where is “magnitude” required...

Read More

February 13, 2020

In 2013, we discussed the OSHA and NFPA requirements for “identifying fire extinguishers” in Fire Extinguishers… Did you know they have to be identified?

In that article, we touched on the OSHA and NFPA requirements for how fire extinguisher LOCATION(s) (not the actual fire extinguishers) are to be identified.

But how many of us see this just about everywhere we go:

Do...

Read More

February 13, 2020

What do you get when you have no “qualified/competent” person on site who fully understands the implementation of a Confined Space program AND OSHA’s eTool Industry page is being read literally by the unqualified worker? The answer: SERIOUS PRCS PROBLEMS! I had a smile on my face the entire time I was thinking about how to write this article in the hopes that industry...

Read More

February 13, 2020

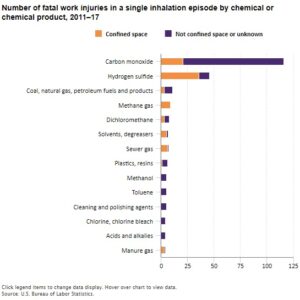

With year 2020 already claiming 7 lives inside PRCSs within the USA, I have to ask the question: Has OSHA’s Permit-Required Confined Space standard meet its goal? In OSHA’s Preamble for 1910.146, published in 1993, OSHA stated:

OSHA has determined that permit spaces pose significant risks to employees (62 fatalities and 12,643 injuries and illnesses annually)...

Read More

February 13, 2020

Why is this article posted in the Permit-Required Confined Space section of the website? Because there seem to be a large number of safety professionals that are under the impression that ANY occupational hazard can turn a confined space into a Permit-Required Confined Space. Noise is a recognized occupational hazard – I think we can all agree on this; however, noise is NOT a hazard...

Read More

February 12, 2020

The Joint TDG-GHS informal working group (IWG) dealing with the categorization of flammable gases was organized in Brussels from 9 to 11 March 2015 by the Belgian and the Japanese delegations to the TDG and GHS sub-committees. The participants (physically/by phone) list can be found in Annex 1of this report. The purpose of this IWG was to review the current criteria and discuss possible...

Read More

February 10, 2020

So many learnings! This happened in the Year 2000. Listen to the radio traffic where the IC is asking for a “headcount”!!!!

Read More

February 9, 2020

I can still remember the day I was told: “the pipe failed its thickness testing – but don’t worry we are going to use a pipe clamp so we can keep using it”. I had just attended my API 570 and 510 courses to learn all about process equipment inspection protocols. Not once did I hear about any “enclosure” that we could put around a leak or a failed inspection...

Read More