SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

January 21, 2020

I am not an electrician, I don’t even consider myself a Qualified Electrical Worker, but I do know Electrical Safety-Related Work Practices (and I stayed at a Holiday Inn Express last week). I do not do a lot of electrical safety training (except for existing clients), but it seems that every time I have done my Intro to Electrical Safety-Related Work Practices I am always challenged on two simple...

Read More

January 20, 2020

Too many safety professionals still to this day think that to reclassify a Permit-Required Confined Space (PRCS) is simply to lock out all the energy sources that made the space a PRCS. In August of last year, I posted a story where I asked the 30,000 members of the SAFTENG network if an enclosed palletizer was a PRCS. (see pic below for example) Overwhelmingly the members agreed that the...

Read More

January 18, 2020

“Minor” LOPC events that are allowed to continue over a weekend can be a COSTLY MISTAKE! Any LOPC event MUST be reported ASAP to that it can be addressed, regardless of how “minor” it may be considered! We have to keep our HHC/EHS’s in their PRIMARY CONTAINMENT and when we have a failure that lets the “tiger out of its cage” we need to address it...

Read More

January 17, 2020

OSHA has cited a refinery for serious violations of safety and health hazards related to process safety management (PSM) following a fire and subsequent explosions at the company’s Refinery Complex in June 2019. The company faces $132,600 in penalties. OSHA’s inspection found deficiencies in the refinery’s PSM program, including failing to establish or implement written procedures, insufficient...

Read More

January 17, 2020

Opening a Natural Gas Condensate line with a battery-operated drill inside a compressor building is ASKING for trouble. Basic HAZLOC work practices include using INTRINSICALLY SAFE tools that are APPROVED for the HAZLOC, which has been an OSHA requirement since 1981…

1910.307(c) Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified)...

Read More

January 17, 2020

Respondent is the owner and operator of a facility that had greater than 10,000 pounds of anhydrous ammonia in a process at each of its facilities. From the time Respondent first had onsite greater than 10,000 pounds of anhydrous ammonia in a process, Respondent was subject to the requirements of 40 C.F.R. Part 68 because it was an owner and operator of a stationary source that had more than a threshold...

Read More

January 11, 2020

Respondent owns a chemical supply outlet where chlorine was present in a process above the 2,500 pounds TQ, and sulfur dioxide was in a present in a process above the 5,000 pounds TQ from at least March 16, 2010. Respondent has two (2) program 3 processes: a chlorine cylinder storage process, and a sulfur dioxide cylinder storage process. Respondent submitted an RMP on March 16, 2010, February 6, 2015,...

Read More

January 5, 2020

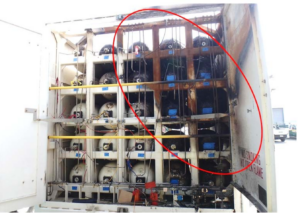

The NTSB has determined that the probable cause of the 2018 Hydrogen tube trailer fire in California was human errors made by two non-related personnel from two different companies with both workers making errors on the pressure relief system:

REQUALIFICATION TECHNICIAN’S installation of an INCORRECTLY RATED PRESSURE RELIEF DEVICE in cylinder No. 14, which actuated during normal transportation and...

Read More

January 5, 2020

Remember that project where we installed new XXXXXXX and to save money we did not remove the old XXXXX and just piped around it? We always thought that the old piping and valves were not a hazard, well think again…

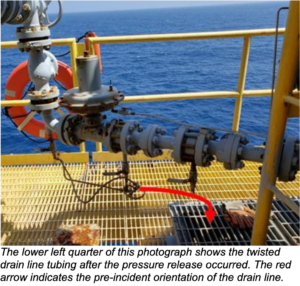

On May 20, 2019, an offshore oil and gas worker was conducting daily rounds, which included checking for fluid in the gas lift fluid slug catcher. The worker noticed that the...

Read More

January 4, 2020

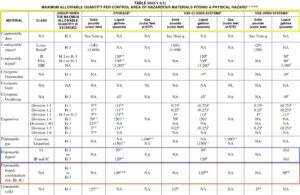

One part of managing flammable liquids is minimizing fuel load in the event there is a fire. Both state codes and OSHA utilize what is called “maximum allowable quantity per control area“. This practice is based on the “degree of hazard” or as OSHA calls them today “Hazard Category” of the flammable liquid or gas being stored/handled/processed. ...

Read More

January 4, 2020

If you’re in the ammonia fertilizer business in the State of Georgia (GA) this may be of interest to you. Although I should point out that the Code language did NOT exclude ammonia held as a refrigerant. On November 25, 2019, the Administrative Procedure Division of the Office of the Insurance and Safety Fire Commissioner held a public hearing on the adoption of a number of proposed...

Read More

January 4, 2020

Over the past decade, we saw a huge swing away from safety being a technical field to one that is more hugs and kisses. Last year, we even saw the number one organization for safety professionals change their name from Safety Engineers to Safety Professionals. Along with the name change came a change to topics at its annual conference and continuing education offerings. This leads...

Read More